One Platform

Integrated Paper Web Monitoring and Paper Web Inspection system – Procemex® OnePlatform

Procemex OnePlatform, is an Integrated Paper Web Monitoring and Paper Web Inspection system. OnePlatform is designed for analyzing paper web breaks and paper defects in one integrated system. This makes it easy for operators to understand the inter-relations between web inspection and web monitoring and move flexibly between the ‘two systems’. Understanding the real root causes for paper defects and web breaks created in the dryers, in the press, and in the forming section has never been easier.

The Integrated Web Monitoring and Web Inspection system, OnePlatform, creates many benefits for the mill operators, production management, quality assurance, IT and paper mill maintenance in their daily work. Resulting to cost savings, enhanced production efficiency as well as material and time savings.

The Key Features of the Procemex OnePlatform system

Empowers the operators to better understand the real root causes for paper defects

The system is not designed for analyzing web breaks and paper defects separately, but to analyze defects in the whole length of paper web within one system.

- One window into the paper web inspection & monitoring world

- Pre-configurable paper defects activate upstream cameras

- Upstream camera viewing area define automatically which cameras are included in the same video

- Web inspection and web monitoring cameras synchronized with each other

- Upstream root cause video evidence is only one click away

Simultaneous analysis of web breaks and paper defects

Procemex OnePlatform Web Monitoring and Inspection User Interface is designed to form one unified user interface, making it easy for paper mill operators to understand the inter-relations between paper web inspection and paper web monitoring and move flexibly between the ‘two systems’.

The intuitive Procemex web monitoring and web inspection user interface makes it easy for operators to understand the real root causes for paper defects and web breaks created in the dryers, in the press, and in the forming section.

System Virtualization and Smart Data Processing Architecture

As the Procemex Smart Cameras process the data already inside the cameras and send the results via TCP/IP Network to the server, there is need for only one server for the whole system. It manages the SQL database for storing and distributing data and communicates with 3rd party systems.

When there is only one computer for the whole system’s data processing, that can contain over 200 cameras, this is beneficial, as it:

- Enables system virtualization by using Procemex server

- Enables system virtualization with preferred customer hardware and service

- Enables parallel server replication

- Enables easy backups

One software and compatible system elements for web inspection and web monitoring enable easy maintenance

In addition to the shared data storage infrastructure and user interfaces, it is also important that there is only one application software covering both web inspection and monitoring. This makes it easy for maintenance and application engineers, as everything is handled in one unified way and there is no need to learn two systems.

Web inspection and web monitoring also share the same lighting and smart matrix camera technology, eliminating multiple spare parts and extensive troubleshooting efforts.

Our Service Team provides system support fast and professionally

When our customers need us, our project managers, field service engineers, remote service engineers and service team experts can quickly provide support for both web inspection and web monitoring issues. Without any application boundaries.

We have a great team of skilled professionals who are dedicated to help you solve the web inspection and web monitoring system problems anywhere, any time. As our client, your mills maintain high performance and receive a quick response in the event of system failure.

SMART CAMERA TECHNOLOGY DEVELOPED IN TAMPERE, FINLAND

One Platform for Longer System Lifetime

We at Procemex are dedicated to build systems that are future proof and backwards compatible. This is our promise to our customers, and its is one of our key values in smart camera development.

The future proof and backwards compatible system can be extended when needed instead of having to be replaced simply due to lack of compatibility.

By developing our own smart camera technology in Finland, we have been able to go beyond the compatibility problems of fast turning computer and off-the-shelf camera world. Many other systems in the market are built on standard technology having an average lifetime of 5 – 7 years due to component obsolescence from OEM hardware manufacturers or lack of compatibility in new components.

Procemex is known for building systems that are future proof and backwards compatible. All our systems starting from 2002 are compatible and can be extended or upgraded.

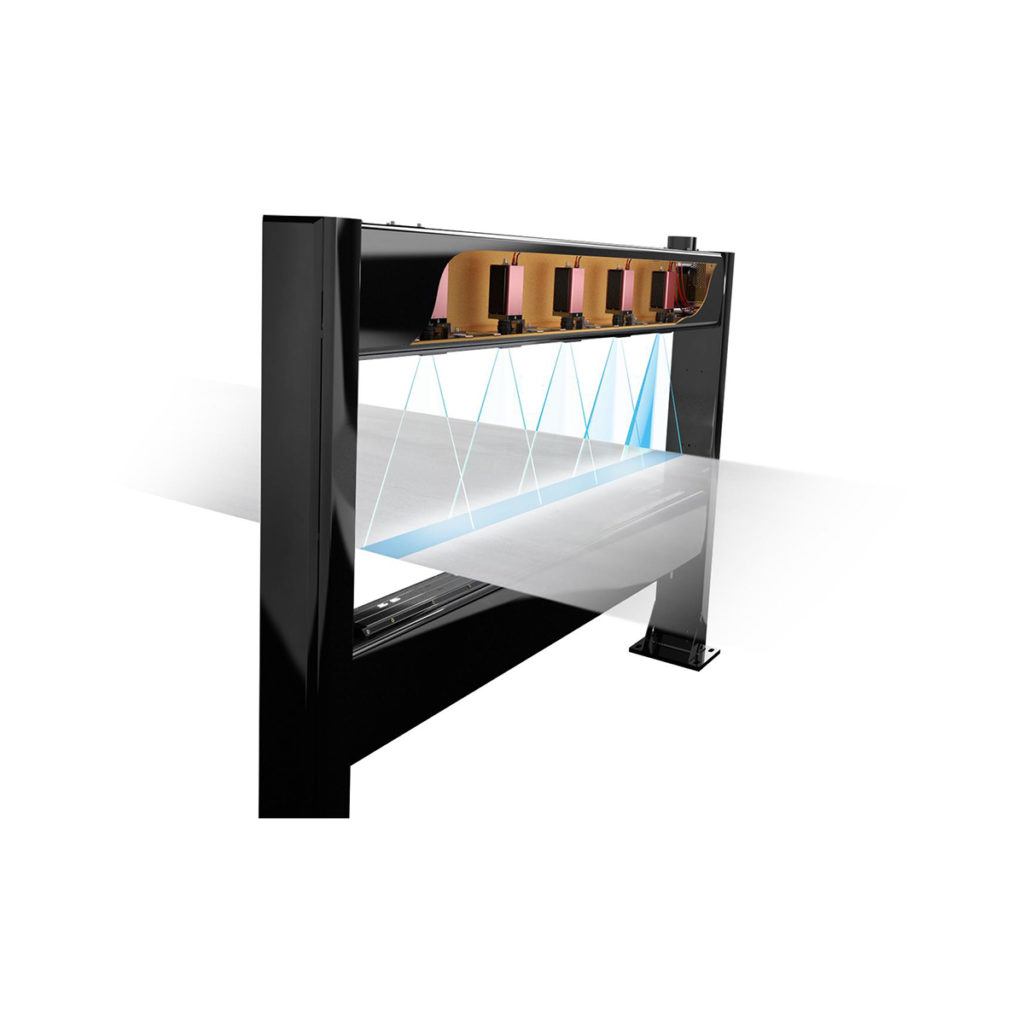

ProClean Pinhole Cameras – stay clean in harsh conditions

The new Procemex ProClean pinhole technology guarantees that cameras stay clean and provide excellent images for operators to monitor web break root causes even in the harshest conditions.

The 12 Megapixel CRYSTAL smart cameras with ProClean technology create sharp images from corner to corner.

Procemex’s ground-breaking ProClean pinhole technology is the superior solution for all pulp, paper and tissue machines. Crystal ProClean Pinhole Cameras can be used in all locations from headbox to the reel.