Clean air technologies – Chile

Custom Solutions to Reduce Emissions and Improve Performance

At ANDRITZ, we specialize in providing customized air quality control solutions that prioritize emission reduction, superior performance, and utmost efficiency. Our mission is to help you adapt to changing market conditions and comply with your asset strategies, while optimizing your environmental impact. Whether you operate in industrial sectors, waste-to-energy or power generation, our comprehensive offer covers the entire exhaust gas line, including particle control, dry and wet scrubbing systems, and equipment for multiple pollutants.

Regulatory Compliance and Lifecycle Optimization

With our broad portfolio of cutting-edge technologies and our commitment to engineering innovation, ANDRITZ is your ideal partner to meet emission regulations and optimize the lifecycle of your clean air technologies equipment. We understand that each industry has unique requirements, and we leverage our expertise to provide custom solutions that meet your specific needs.

Sustainability and Environmental Responsibility

At ANDRITZ, we recognize the importance of clean air and a healthy environment. Our advanced engineering tools and our global collaborations in research and development enable us to stay at the forefront of clean air technologies. We work closely with recognized partners and universities to ensure that our solutions contribute to long-term environmental sustainability.

Maintenance for Precipitators and Bag Filters

Proper maintenance of electrostatic precipitators and bag filters is essential to ensure optimal performance and a prolonged lifespan for these pieces of equipment.

- Regular Inspection: Carry out periodic visual inspections to identify any damage or wear in the electrostatic precipitators and bag filters. Look for signs of leaks, wire breaks, cracks in insulators, and excessive wear of the bags.

- Bag Cleaning: The filter bags can accumulate dust and particles over time, which reduces their efficiency. Schedule regular cleanings to remove dust buildup. You can use methods such as shaking the bags or using compressed air to remove adhered dust. If necessary, consider washing the bags with water and mild detergents.

- Electrode Check: Electrostatic precipitators feature electrodes that can accumulate deposits of dust and dirt. Inspect and clean the electrodes regularly to maintain their efficiency. Make sure to follow the manufacturer's recommended procedures to avoid damaging the electrodes during cleaning.

- Replacement of Damaged Bags or Electrodes: If you find damaged bags or electrodes during inspections, be sure to replace them immediately. Torn bags or broken electrodes can affect the system's performance and reduce its particle capture efficiency.

- Control Systems Calibration: Electrostatic precipitators and bag filters are often equipped with control and monitoring systems. Carry out regular calibrations to ensure that these systems function correctly and provide accurate measurements.

- Preventive Maintenance Program: Establish a preventive maintenance program to carry out tasks such as equipment lubrication, checking of electrical connections, inspection of bag cleaning systems, among others. This will help prevent future problems and keep the equipment in optimal condition.

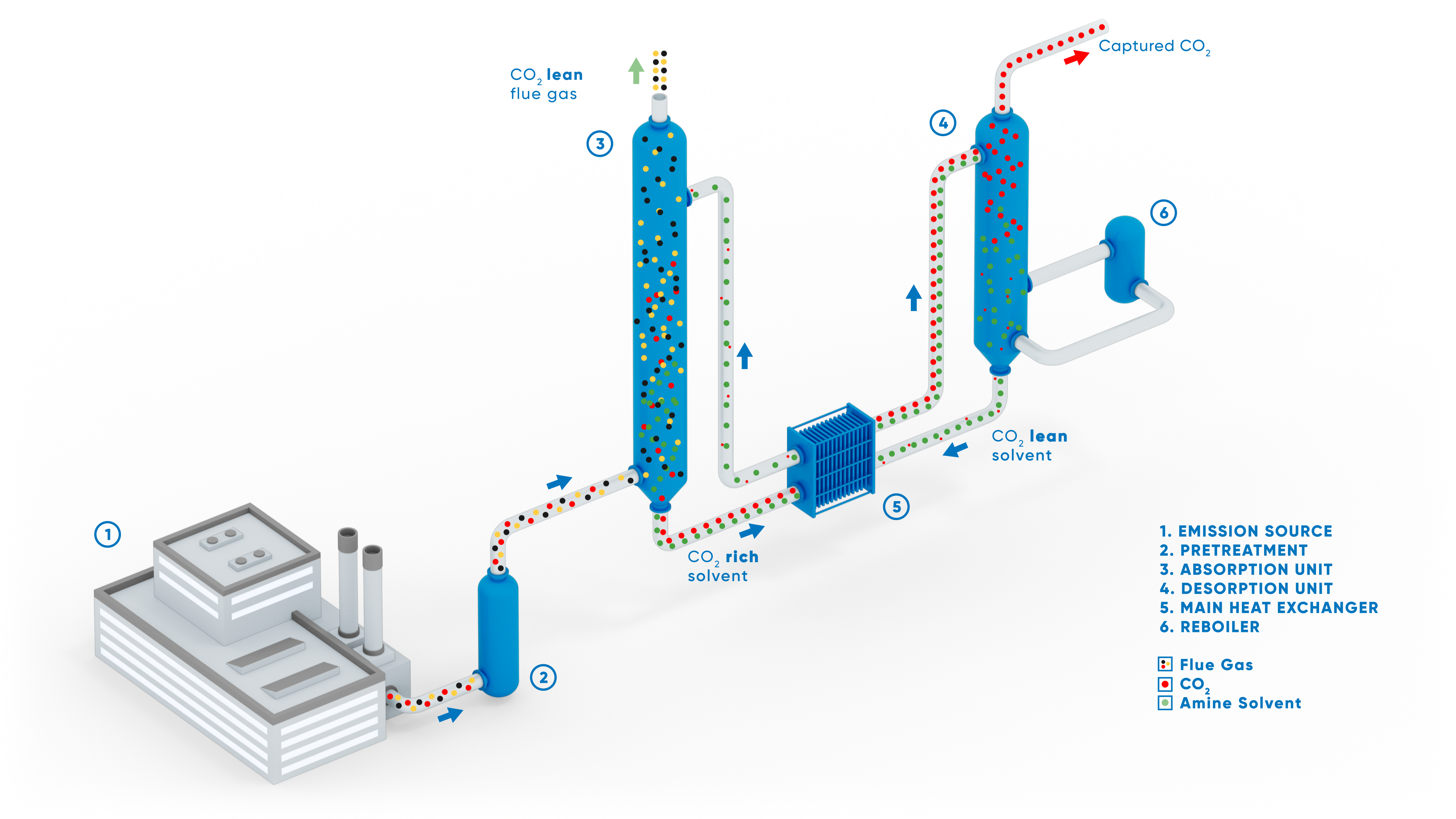

ANDRITZ Carbon Capture - Chemical Absorption (Amines)

ANDRITZ Carbon Capture - Process Flow Diagram (Amines)

Contact us now to discuss your air pollution control needs. Our dedicated team is here to answer your questions, provide expert advice, and work with you to find the ideal solution for your business.