By the way: The word hygiene comes from Hygeia, the Greek goddess of health, who was the daughter of Aesculapius, the god of medicine. (Source: History Learning)

Making human life cleaner

The ANDRITZ experts in hygiene know a lot about personal protection and how to keep substances out that are harmful to our health

ANDRITZ Diatec, as part of ANDRITZ Nonwoven, is a renowned technology specialist for machines that are used all over the world for the production of hygiene end products: diapers for both babies and adults, feminine hygiene or underpads, but also gloves and protective clothing for the medical sector and food pads for the food industry.

Hygiene and civilisation - two inseparable concepts

The true heroes who made the world more hygienic have long since passed away. For example, the inventor(s) of the sewerage system or soap, whose origins go back a long time to the time before Christ. But even in modern times, engineers, chemists and other natural scientists have continued to work on improving hygiene. The degree of a civilization can be measured by its standards of hygiene. Along with this, the findings in medicine.

With the Age of Enlightenment, the interplay of medical progress and hygiene rules became increasingly more important and the outbreak of serious epidemics was curtailed more and more as from the early 18th century.

With the beginnings of bacteriology and virology at the end of the 19th century, the foundation stone was finally laid for the concept of hygiene as we know it today.

Hygiene and fighting the diseases caused by hygiene deficiencies are an important prerequisite for a modern civil society and a high degree of personal freedom.

In the Greek mythology the source of hygiene: Hygeia, the Greek goddess of health

© Adobe Photo Stock | ArchivistHygiene standards are a fundamental right of every human being

But the progress from which we in the Western world have already benefited for several decades is still a long way from reaching all parts of the globe. Much of mankind still lives far away from sources of safe drinking water or sanitary facilities that can at least come close to our Western standards.

This also includes the availability of products that make it easier for us to maintain hygienic conditions more effectively, and this is where the nonwovens industry plays a special role: Disposable products made of nonwoven materials in particular have undergone revolutionary changes, even if these changes have largely taken place in silence.

Who can still imagine today that baby diapers were made of textiles less than 60 years ago in large parts of Europe and had to be laboriously cleaned and washed? This work was left almost exclusively to women, many of whom did not have the time to devote themselves to their own professional training, education and career due to all this laborious manual work.

In this respect, it can certainly be said that modern hygiene products also had an influence on female emancipation or at least promoted the idea of freedom for women in their personal development.

Classic diaper, made of cloth: In use until the 60s and 70s in the US and Europe

© Adobe Photo Stock | PixieMeBy the way: During World War II, the increase of working mothers brought the need for the "diaper service" which would increase in the years to come. (Source: Diaperjungle)

So it is not surprising that it was a woman – Marion Donovan – who developed the concept of disposable diapers. Nevertheless, it is also true that a large part of the world's female population still has no access to freedom in their own personal development.

Nonwoven products keep us clean

The world and the people living within have become much “cleaner” thanks to nonwoven products, even though the disposal of these products often creates new problems. In addition, there have been numerous developments in the field of environmental compatibility that can put an end to the flood of waste from disposable products by using natural fibers or renewable fiber materials.

In any event, the use of disposable products from nonwovens production is a cornerstone of the progressive advancements made nowadays in the hygiene sector around the globe.

Today, it is impossible to imagine everyday life without end products made of nonwovens. In addition to diapers for babies and adults, these are mainly hygiene pads, cleaning and cosmetic tissues, moist toilet paper, medical protective clothing and clothing for other hygiene-intensive industries such as food, but also femcare products or face and respiratory masks.

We are almost invisible – but you can feel us

People often know some brand names or the names of the companies behind numerous nonwoven end products, be it baby diapers, cosmetic wipes or moist cleaning wipes. However, the manufacturers of the machines that produce all these things are probably only known by a few. ANDRITZ is one of these brands that are invisible to most people, working far behind the scenes to ensure that the products are constantly evolving, constantly improving their properties, and conserving resources with new, sophisticated methods. But as a consumer, you can feel the quality of the products made on machines from ANDRITZ. Naturally, this is achieved in cooperation with fiber producers and with research and testing facilities all over the world.

ANDRITZ Nonwoven serves two main and important stages in the nonwoven value chain. On the one hand, they design machine systems for the production of base materials. Early on, in the forming stage, the fiber materials are fed in directly and semi-finished products are created for further processing in numerous industries: automotive, geotextiles, furniture textiles and the carpet industry, in construction – and in the large sector of hygiene products. The different manufacturing processes differ mainly in the way the fibers are introduced into the production process, i.e. in the forming process, and how the material is joined together (needlepunch, hydroentanglement, thermobonding by calendering, heating and fusing of the fibers in ovens – it always depends on what the customer wants to produce for which branch of industry).

On the other hand, ANDRITZ is also represented in the converting sector of the hygiene industry, i.e. machine lines that process the above mentioned materials to make valuable end products for the mass market. ANDRITZ Diatec is the ANDRITZ Group company with a focus on this sector.

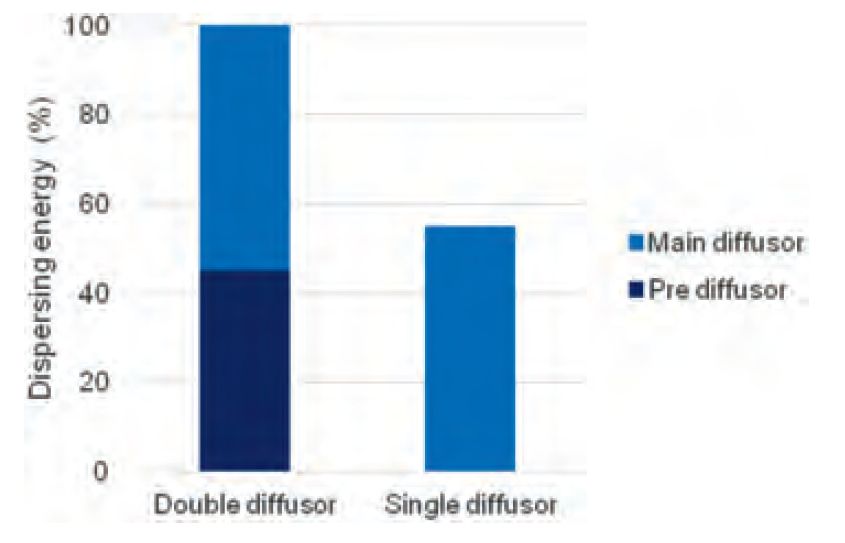

Dispersing power of double diffusor vs. single diffusor

ANDRITZ Diatec - the technology that helps to make the world cleaner

The D-TECH production lines are aimed at customers who want to produce high-quality baby and adult diapers, pants, underpads and laminated products for medical gloves or food pads for example, and also face and respiratory protection masks such as those used in operating theatres in hospitals and doctor's surgeries, and, since the Covid-19 pandemic, increasingly in private households and public places worldwide.

The many years of experience gathered by ANDRITZ Diatec's engineers have made them true experts in the various product categories.

Efficiency, low waste rates, optimization of energy consumption, and short maintenance times are core features of all ANDRITZ Diatec machines. For example, the new D-TECH face mask produces up to 750,000 masks per day, depending on composition and mask type, and is thus five times more productive than many other machines for face mask production.

Discover the world of ANDRITZ Diatec – it can make much more out of your spunlaid or spunlace technology and also help to make the world a little cleaner.

High efficiency in the production of baby diapers

face mask eXcelle pilot line