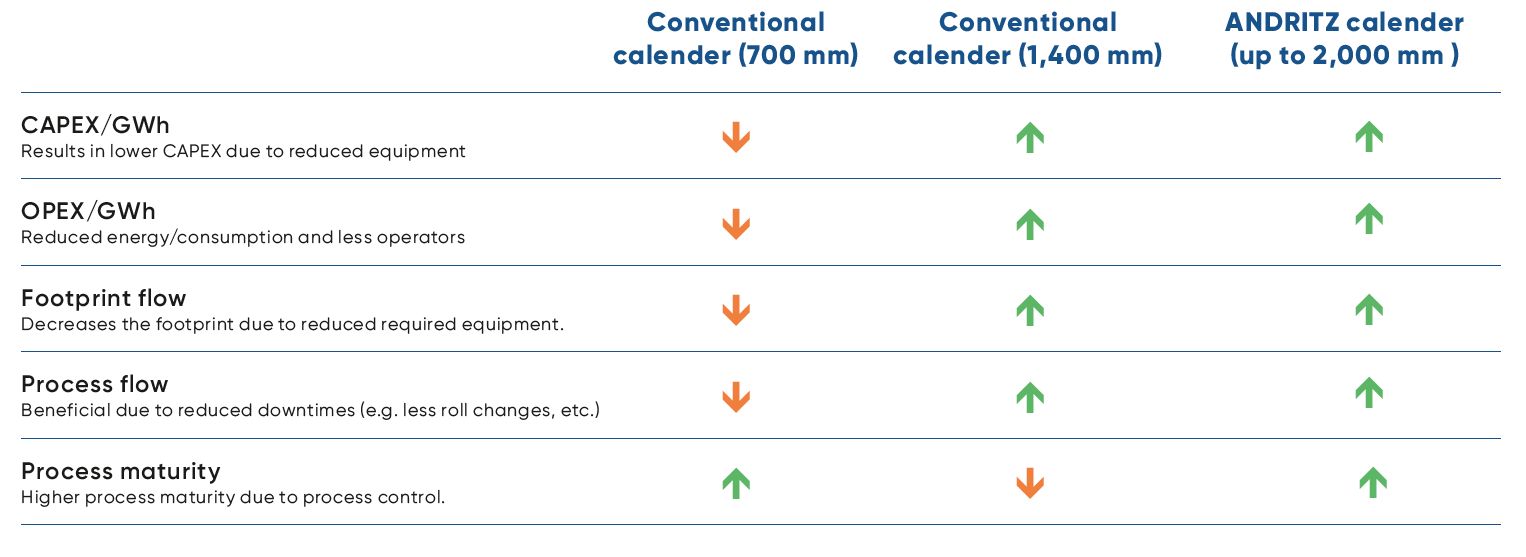

Current production set-up

A calender is an essential part of the wet coating process for the production of electrodes for batteries. Within this process a uniform product thickness and stable quality are of utmost importance. For coating and drying, a product width of 1,400 mm is state-of-the-art. However, a calender of this width cannot meet the technical product requirements yet.

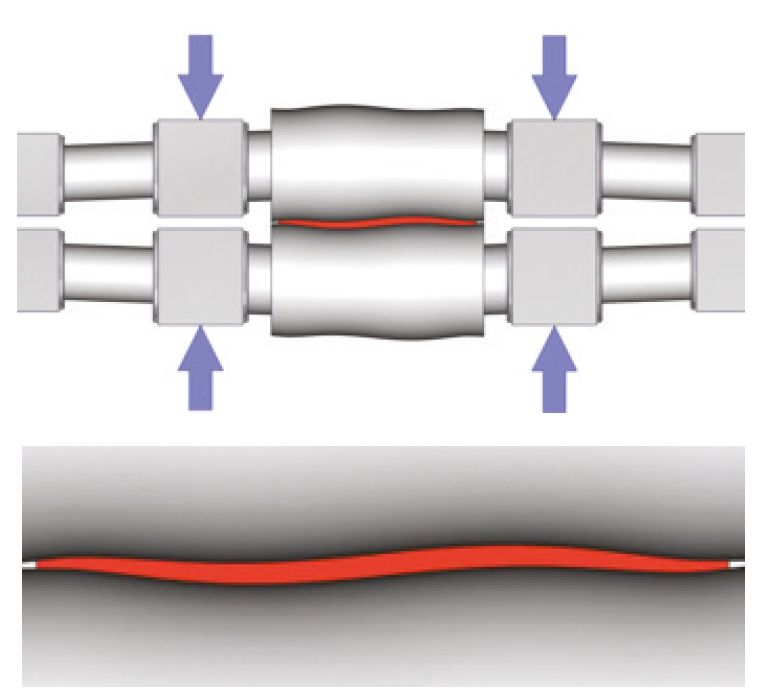

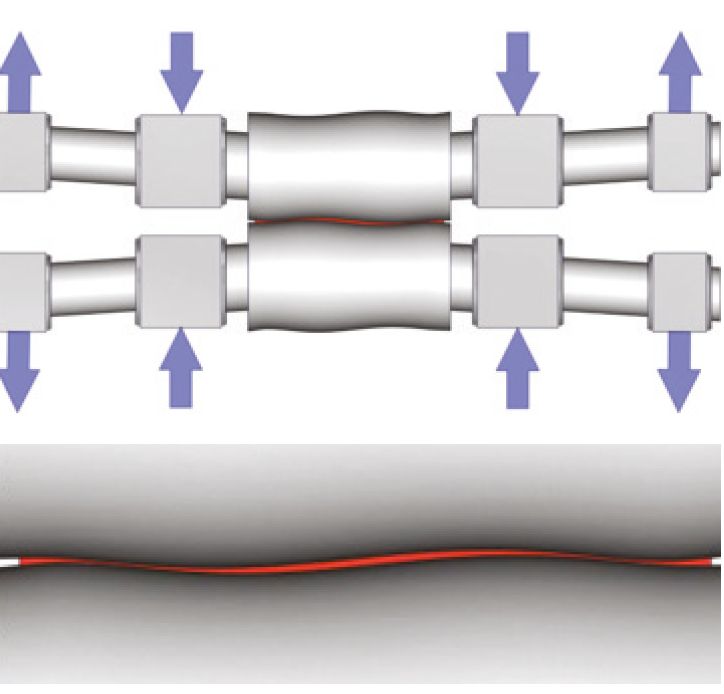

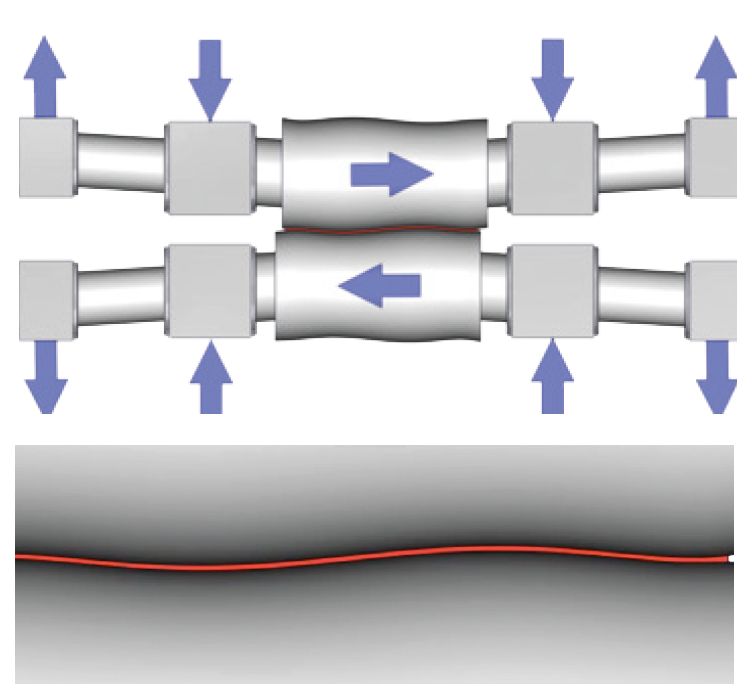

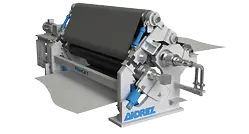

Thus, an acceptable thickness deviation cannot be reached with one calender only. This is why a center slit and two calenders in small product widths are needed for the current process. In addition, conventional calenders, create a so called W-profile, by activating roll bending in the second step. This profile is acceptable for narrow working widths. For larger widths, the product thickness deviation is out of tolerance.