Comprehensive Testing

Software-driven testing evaluates a complete set of plant upsets, enabling your engineering team with detailed trends of the plant response under a wide range of operating and upset conditions. Test scenarios are generated and executed automatically based on user-defined rules that rigorously analyze the failure consequence of every piece of the plant.

IDEAS HAZOP was born from our experience supporting the operational analysis of capital projects. In a traditional HAZOP, the determination of what will happen when each piece of equipment fails is a discussion, rather than a rigorous engineering evaluation. Instead of hypothesizing about what will happen in each scenario, we provide a report that contains trends of what happens to key variables in each case.

Industry-Best Simulation Technology

The core of trustworthy analysis is dependable models. IDEAS contains the best available physical models of each piece of equipment, creating a package that accurately represents the chemical reactions, thermodynamics, fluid mechanics, and material transport which make up the plant. The models are all constructed using normal engineering dimensions, such as pump curves, pipe diameters, and tank volumes. Our models have been verified repeatedly over 25 years in a wide range of applications.

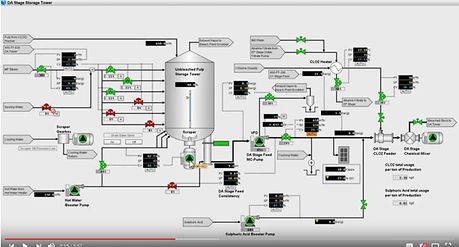

Full Control Strategy Analysis

We model the complete control strategy, using logic libraries that mimic control system behavior. The result is a virtual plant that can represent complex interactions between process transients and interlocks across an entire plant area.