Advantages of the LimeWhite-H:

- Continuous operation

- Clean and hot white liquor

- Fully automated

- Higher white liquor yield

- Reduction in water circulation

- Less white liquor dilution

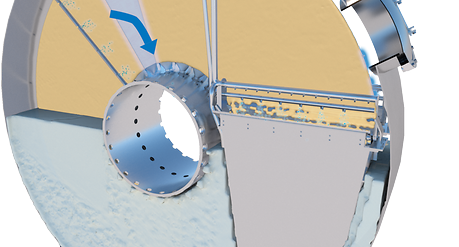

The ANDRITZ LimeWhite is a pressurized disc filter, which performs both white liquor filtration and lime mud washing. High discharged mud solids makes it an ideal selection for mills with tight water balances.

ANDRITZ offers now also LimeWhite-H as an upgrade version for previous LimeWhite. ANDRITZ LimeWhite and next generation LimeWhite-H filters provide the best white liquor quality with high availability.

The next generation lime white filter

ANDRITZ has completely remodeled its existing LimeWhite filter solution and introduced the latest next generation filter for pulp producers, LimeWhite-H. The new filter has major benefits including lower investment cost, increased capacity and a smaller footprint.

One of the major innovations of the new LimeWhite-H is the introduction of a center shaft with axial movement which allows continuous precoat renewal with no moving scraper, eliminating the need for low pressure washing.

The LimeWhite-H contains a hollow shaft. This means no inner piping inside the shaft itself. This makes a big difference, since higher capacity can be achieved with the new design.

Due to the higher vat level, the filtration area is larger in the new design. Vat level can be raised up to half of the center shaft. Over 30% increased capacity has been measured with this new filter design and without any build-up of lime mud on the shaft.

A new lime milk feeding point has been created through the bottom of the filter through the air agitators. Previously, the feed point was from the side.

In the new LimeWhite-H filter there is higher pressure difference through the discs’ filtering cloths that enables higher capacity.

During normal filtering operation the new LimeWhite-H filter slurry water is sprayed directly onto the scraper to ensure efficient dilution of lime mud and also keeping scraper blades clean.

At some stage of normal filtering operation when the pressure difference over the precoat increases to set point wash down sequence starts. During this wash down sequence the shaft starts to rotate in a reverse direction and at the same time high pressure water jets remove the precoat. This ensures that the lime mud falls into the chute instead of the vat. This function replaces the previous precoat blow-off system design.