Second step: Highly efficient separation

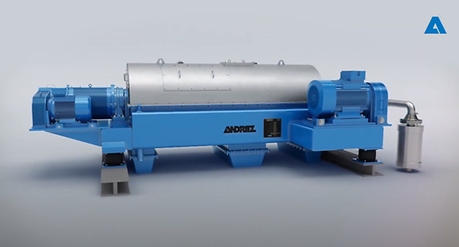

The CENSOR ACZ, the core unit of the process, is a sorting centrifuge that separates, washes, and dewaters the raw material all at the same time. The centrifuge is partly filled with a separation liquid (normally water), forming a liquid ring due to high-speed rotation. Intense turbulence within the machine results in deagglomeration of the individual plastic particles and largely frees them from any adhering dirt. Light and heavy solids (fractions) are discharged separately. Whereas the heavy fraction can be further processed or sent to disposal, the light fraction is a highly valuable secondary raw material perfectly suitable for extrusion and injection molding. Depending on the type of plastics to be separated, the CENSOR ACZ achieves purity of more than 99.8% with very low losses of valuable product.