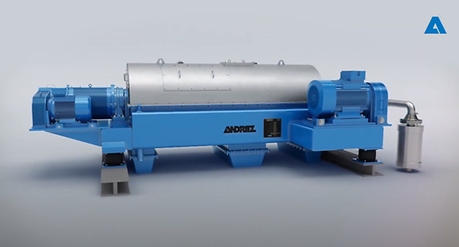

ANDRITZ decanter centrifuges Censor ACZ for efficient plastics recycling

Setting standards in plastics recycling

Plastics recycling has become much more specialized. The recycling aspects are being included more and more in the conception of new products. New, improved technologies have been developed in response to current concerns about the recycling of products at the end of their lifetime. These technologies now include the recycling of post-consumer carpets.

ANDRITZ CENSOR ACZ Centrifuge for plastic recycling

New applications have emerged for recycled plastics in all areas of plastics processing, such as film or profile extrusion, blow molding, and injection molding. However, the most important requirement in plastics recycling is product quality. Reliable specifications for MFI, specific density, modulus of elasticity, color, and so on must be provided to verify quality to potential customers.

Only pellets that meets these stringent demands will have a chance on the market in the long term. ANDRITZ centrifuge technology offers the means of meeting these high standards. It ensures constant outstanding quality of the regranulate.

Applications

- Post-consumer waste

- Industrial waste

- Production waste

- Technical plastics

- Films

- Bottles

- Carpets

- Fibers

- Plastics from the automotive industry

Benefits of the ANDRITZ decanter centrifuge ACZ for plastics recycling

Economical

- Low fresh water requirement

- Low space requirement

- Simple operation

- Low energy demand

- High availability

Ecological

- Minimal waste water discharge

- High selectivity means maximum recovery

Process

- High selectivity

- Clean products

- Little loss of valuable materials

Technologically advanced

- Proven modern machine technology

- ANDRITZ decanter centrifuges of modular construction, manufactured in series

The operating principle

The core unit of the process is the sorting centrifuge, which separates, washes, and dewaters the products simultaneously.

The operating principle is shown in the schematic diagram. The commingled plastics, which are normally pressed in bales when they arrive at the recycler site, are reduced to a particle size of 15 mm, mixed with separation liquid (usually water) in a mixing tank, and then pumped to the centrifuge.

The centrifuge is partly filled with a separation liquid, which forms a liquid ring due to rotation at high speed. The plastics are fed axially into the centrifuge as a suspension and impinge on the surface of the revolving liquid ring. Here, intense turbulence results in de-agglomeration of the individual plastic particles and largely frees them from adhering dirt.

Any air bubbles adhering to the surface of the particles are stripped off by the centrifugal force, which is especially important in view of the predominantly hydrophobic material. All particles with a density greater than the liquid are forced outward radially to the centrifuge bowl, while lighter components float upwards inwardly. This occurs in a very short time and with high selectivity in a centrifugal field creating forces over 1,000 times higher than in conventional processes. The particle shape and size are not significant here.

A screw conveyor rotates inside the centrifuge at a speed slightly different to that of the centrifuge bowl.

Censor ACZ, an all-in-one solution for separating, washing, and dewatering

Ventilation opening of the ANDRITZ decanter centrifuge ACZ

ANDRITZ recycling technologies: Recover raw materials. Maintain values.

Innovative recycling technologies for material separation and recovery, treatment of various types of waste and rejects, and the production of renewable energy help you reduce dependency on purchased power and eliminate landfilling of waste - thus making substantial contributions towards protecting the environment.