Food & Beverage

- Animal processing

- Wine, juice, beer, dairy

- Mash filtration for craft beers

- Baby food

- Functional ingredients

- Industrial fermentation

- Nutraceuticals

- Starches and protein

- Sugar

- Vegetable oil

Efficiency, cost-effectiveness, and maximum flexibility for industrial filtration processes. Therefore, ANDRITZ provides a wide selection of industrial filter presses, including both sidebar and overhead types, suitable for various applications from laboratory to industrial scale. Our product line includes chamber, membrane, and heated filter presses, offering versatility with different energy sources and efficient operation. And the combination with our innovative automation solution – the Metris addIQ control system – ensures operational efficiency, cost-effectiveness, transparency, and straightforward training requirements.

For the most sophisticated separation tasks, a fully engineered design might be the best solution. These technical solutions are especially suitable for food and pharmaceutical applications, rough environments, and hazardous suspensions, and include:

Various feed port positions

Scraper

Vibrating device

Second feed inlet

Safety guards

Splash guards

Raised press frame

Second filtrate outlet

For some filtration challenges in the food and chemical industries, our offer includes in addition:

Stainless steel cladding

Rubber lining or PP coating

Mobile filter press units

Benefit from the broadest and unmatched filter press portfolio of both sidebar and overhead filter presses, whatever your application is.

ANDRITZ offers a complete filter range from laboratory presses to standard to heavy-duty and from chamber, membrane to heated filter presses. Maximum flexibility can be achieved through a variety of different power sources, so there is a range of well-known performance brands and different levels of automation to choose from. Even provisions such as ATEX, GMP and others can be met with ANDRITZ filter press technology. Low power consumption, easy operation and thus low training requirements. other advantages. ANDRITZ filter presses are flexible because they can be easily upgraded, which is especially important when process parameters change.

By using an ANDRITZ filter press, drinking water can be recovered and thus recycled in the process. This saves process water and reduces operating costs while achieving the highest product purity. Even changes in legislation/environment regulations or customer requirements can be met using post-treatment filtrate. With the wide portfolio of downstream equipment offered by ANDRITZ, such as dryers or evaporators, further processing is easy.

With ANDRITZ filter press technology, you are prepared for the challenges of digitalization and IIot – All to the degree that fits your individual needs. IIoT for filter presses ensures that productivity is maximized and bring our customers with the following advantages:

ANDRITZ offers a wider range of filter presses with sidebar technology suitable for both standard and medium duty, and for heavy-duty performance levels. Maximum flexibility is provided by choosing between simple manual to fully automated ANDRITZ sidebar filter press designs. ANDRITZ sidebar filter presses are upgradable in terms of modules and features and can be customized to your specific needs.

The product range comprises frame, sheet, chamber, and membrane filter presses up to a size of 2,000 x 2,000 mm and an area of approx. 1,300 m². The filtration pressures range from 7 to 30 bar.

Sidebar filter press

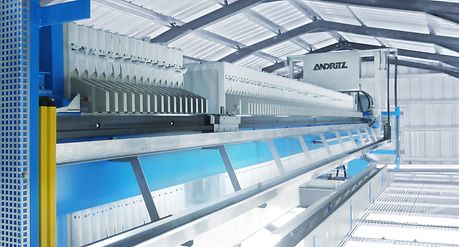

ANDRITZ overhead filter presses are used for processing media where high throughputs are required per machine and free access to the plate pack is also necessary. ANDRITZ overhead filter presses are upgradable in terms of modules and features and they can be customized to your specific needs. In overhead filter presses, the plates are shifted via the overhead beam. Thus, free access to the plate package is ensured from the side.

The product range of ANDRITZ overhead filter presses comprises chamber and membrane filter presses up to a size of 2,500 x 2,500 mm and an area of 2,000 m². The filtration pressures range from 7 to 30 bar.

Less peripheral equipment, resulting in lower investment and OPEX costs: Chamber filter presses are reliable and robust in many different applications. The plate pack consists of uniform chamber plates with a recess of 15- 50 mm to receive the filter cake. The standard material for chamber plates is polypropylene. Possible operating pressures: 6 bar, 15 bar, and 30 bar.

Higher DS content obtained with membrane filter presses: Membrane filter plates are designed in the same way as the chamber plates described above. A flexible membrane is secured to the support body. The membrane is impermeable and compresses the cake within the chamber after the filtration process has been completed. Liquid or gas can be used as the membrane inflation medium. Inflation pressures up to 30 bar are possible, and in special cases even higher.

Quick filter cloth change for process filtration: The chambers in this type of filter press are formed by combining polypropylene filter plates and frames. This creates chambers of 5-40 mm, depending on frame thickness. Plate and frame type filter presses are suitable for pre-coating filtration, which is used in the beverage industry for clear filtration. ANDRITZ supplies plate and frame type filter presses for operating pressures up to 6 bar.

Whether you need spare parts, local service, repairs, overhauls, or modernization of your filter press, ANDRITZ– as the OEM behind Rittershaus & Blecher and Netzsch Filtration – is your full-service provider when it comes to overhead and sidebar filter presses with different filter element technologies like chamber filter presses, membrane filter presses, as well as plate and frame filter presses.

Find more information about ANDRITZ filter press service solutions