Improving your operation with Metris Digital Twin Technology

What is a Digital Twin

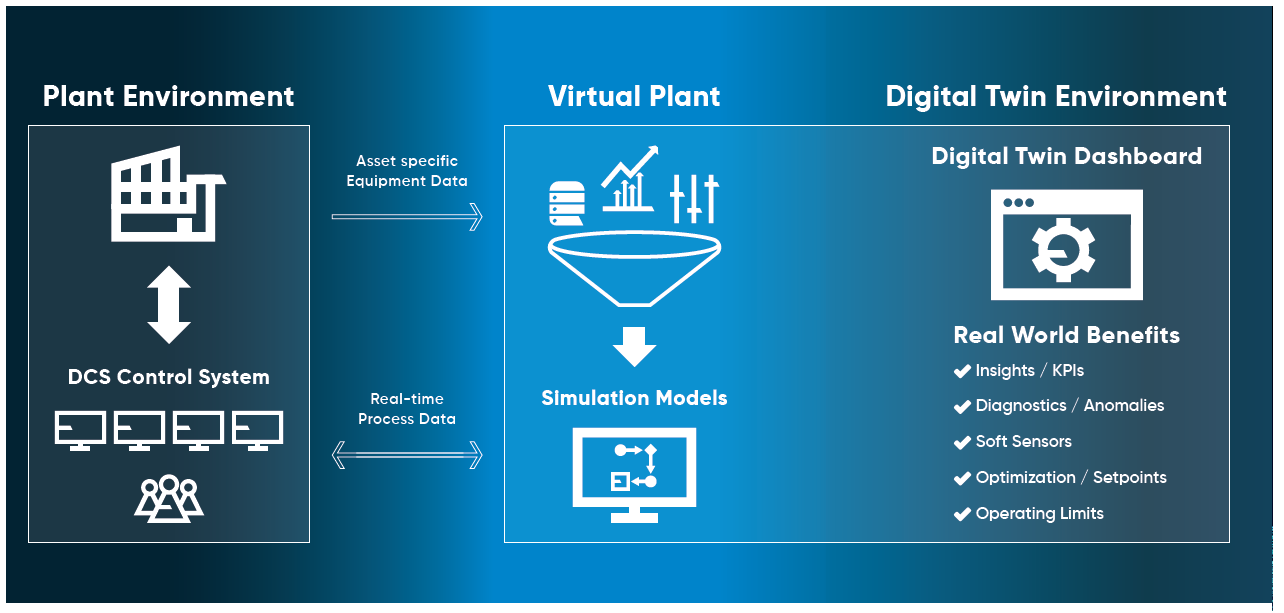

The Metris Digital Twin represents an up-to-date digital replica of the physical asset—a process or a piece of equipment.

The Digital Twin of a process plant is analogous to an MRI of the human body, providing otherwise invisible insights to assist operations with proactive and consistent decision-making.

These high-fidelity simulation/machine learning models transform the real-time process data into meaningful and actionable steps while following the changes of its physical counterpart.

When connected to online plant data, the Digital Twin acts like a performance information tool like an MRI of the human body.

Modular approach and integration with existing Automation ecosystem

Dashboards with valuable information

This modular approach offers multiple benefits for meaningful integration depending on customers assets digital maturity. This also makes space for other digital solutions to coexist.

The applications are typically installed on-premises virtual machines within the same OT network, communicating with the plant DCS/PLC/Historian to read/write real-time plant data as an OPC Client.

ANDRITZ also provides the software, services, and process expertise to deploy and integrate Digital Twin solutions into your existing Automation ecosystem.

Metris Digital Twin solutions for Pulp mills

Revolutionizing Pulp Mill Operations with Advanced Digital Twins for Enhanced Efficiency and Sustainability

Pulp Dryer Digital Twin

Evaporation Digital Twin

- Kiln Digital Twin

- Recaust Digital Twin

Recovery Boiler Digital Twin

- Bleaching Digital Twin

- Cooking Digital Twin

- O2 delig Digital Twin

- Screening Digital Twin

- Washing Digital Twin