“Sustainability is a major winner with the Smart Series and is a subject close to my heart,” adds Johanna. “Reduced energy consumption (from refining for example), minimized carbon footprint, improved process efficiency – all are logical consequences of a process optimized through turning data from smart instrumentation into knowledge. Safety is another critical aspect of sustainability which is also addressed through autonomy, by distancing operators from potentially hazardous tasks through robotics and mechatronics.”

Unique challenges

”The wide range and constant variability of fiber sources for pulp and paper mills presents a unique challenge,” adds Stephan Keuschnigg-Zingl.“ There are also sidestreams, such as methanol and biofuel becoming more and more important for our customers. So, it is important that at ANDRITZ we are more than an integrator: we own and actively develop the products within the Smart Series portfolio that make a difference for our customers to run their operation in an efficient and sustainable way.”

The latest examples are NAF control valves, which brought process flow control into the portfolio in May 2024, Procemex, which added machine vision capabilities in June 2024, and the latest in August, PulpEye an innovative analyzer and measurement technology company, their products contribute to stabilized and higher pulp quality, process efficiency and reduced energy consumption in pulp production.

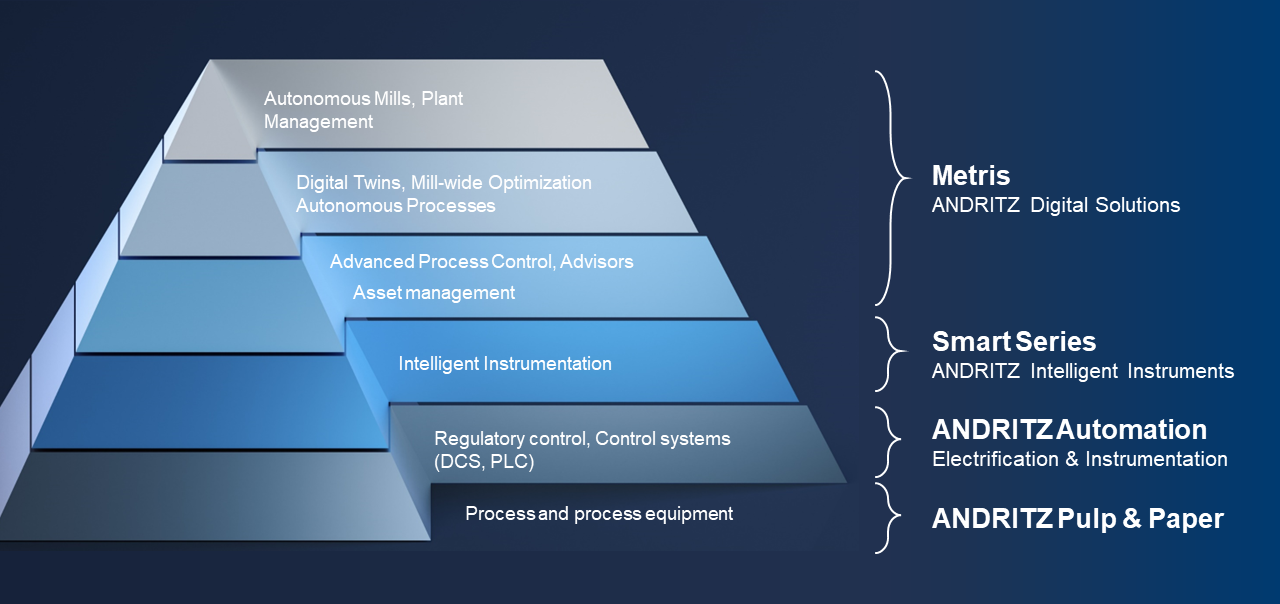

Smart Series typifies the benefits of the One ANDRITZ approach. ANDRITZ’s experience and knowledge in process, service and automation puts it in a position of strength to take the entire value stream’s efficiency to a new level with Smart Series, enabling process and plant autonomy. It’s not just about delivering a smart product but sustaining and enhancing the benefits which that product provides over time, not only in a single process area but to support our customers to automate and digitalize their entire production value chain.

ANDRITZ launched the Smart Series of intelligent instruments at Pulp & Beyond in Helsinki, Finland in April 2024.