ANDRITZ PULP & PAPER: Pioneering Mill Optimization with the 3S Program and D-Floc-It Technology

ANDRITZ continues to lead the industry with innovative solutions designed to enhance mill operations. With the introduction of the 3S program (Safety, Support, Success) and the exclusive D-Floc-It technology, ANDRITZ is setting new standards in efficiency, reliability, and product quality.

The 3S Program: Safety, Support, Success

Safety: A Solid Foundation

The 3S program begins with a strong emphasis on Safety through its safety-to-success initiative, guaranteeing zero risk. This initiative ensures a safe starting point by providing a reliable alternative supply of refiner plates, according to the specific needs of each mill. To minimize risk ANDRITZ provides equivalent refiner plate designs from the start

The first step is to secure the supply, potentially through make-and-hold and/or consignment contracts, as well as stock monitoring. Understanding the unique challenges faced by mills, ANDRITZ guarantees that all safety measures are customized and rigorously upheld, laying a secure foundation for all subsequent operations.

Support: Building Trust and Reliability

The second pillar, Support, underscores the importance of reliable mill operations. ANDRITZ provides comprehensive support through a dedicated team of experts, ensuring that each mill’s specific needs are met. This includes analyzing the mill's operations and reviewing best practices to optimize performance. Additionally, ANDRITZ offers high-quality refiner plates and other essential components, backed by an in-depth understanding of the mill's operational context. This approach builds trust and ensures long-term reliability and performance.

Success: Continuous Improvement for Sustainable Success

The final pillar of the 3S program focuses on driving Success through continuous improvement. The ANDRITZ team presents a series of optimization steps, carefully evaluating their risks and potential gains. This low-risk continuous improvement program helps mills achieve significant enhancements in efficiency, productivity, and overall performance. By utilizing ANDRITZ's wide range of refiner plate design technologies, the program addresses the customer's specific needs and targets, ensuring tailored solutions for optimal results.

D-Floc-It Technology: Revolutionizing Refining Efficiency

Complementing the 3S program as a part of the Success -pillar, ANDRITZ’s exclusive license *) of the D-Floc-It technology introduces a revolutionary refining zone that promises to transform mill operations. D-Floc-It technology is only one example as ANDRITZ offers a variety of different design and technology solutions to further enhance mill efficiency and performance.

Unmatched Efficiency and Energy Savings

D-Floc-It technology significantly reduces energy consumption by 10-20%. This substantial improvement not only lowers operational costs but also supports the industry’s sustainability goals. By optimizing the refining process, mills can achieve energy savings while maintaining high performance.

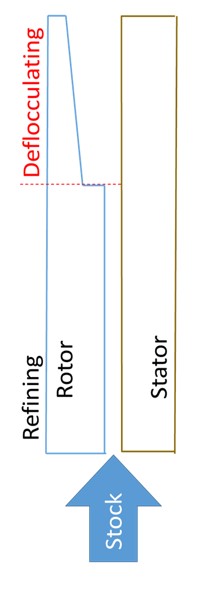

Reducing Stringing and Enhancing Product Quality

One of the key benefits of D-Floc-It technology is its ability to remove fiber flocs from the stock and reduce stringing in the headbox, which is crucial for maintaining a smooth and consistent production flow. This reduction in fiber flocs and stringing directly contributes to improved product quality and operational efficiency.

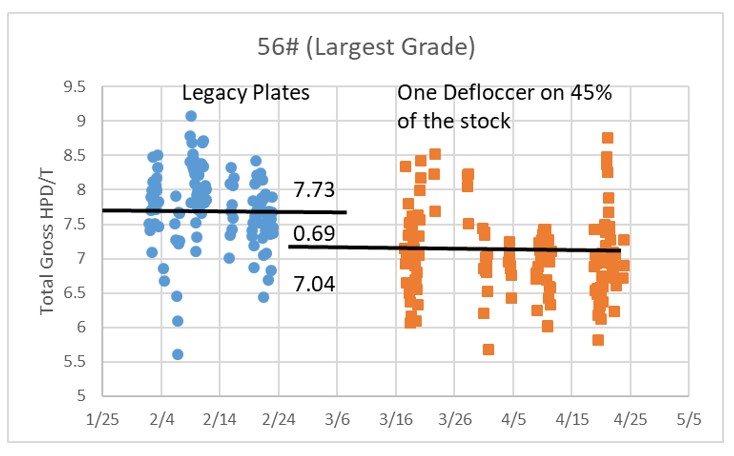

Superior Sheet Structure and Strength Development

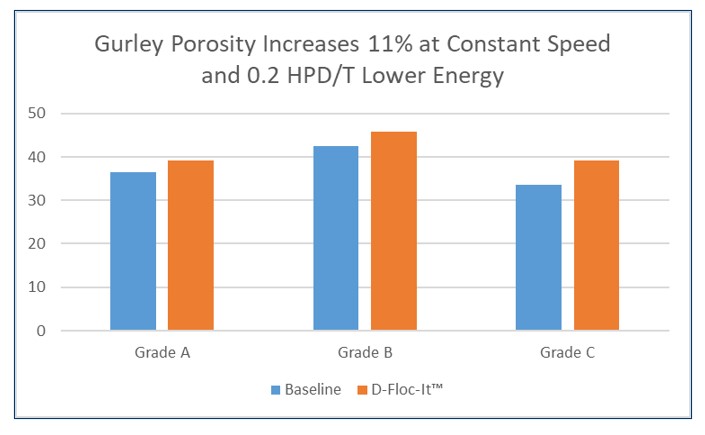

D-Floc-It technology excels in creating a better sheet structure while saving energy. It enhances the structural properties of the sheets, making them stronger and more durable. According to the findings of one particular case study, it can increase Gurley Porosity by 11%, a significant improvement that does not compromise energy efficiency. This dual benefit is vital for producing high-quality paper products that meet market demands.

- High yield softwood Kraft liner

- Defloccers shown in gold

- At the same machine speed, Gurley Porosity increased 11% on average with 4 kWh/T, a slight reduction in specific energy.

A Comprehensive Approach to Mill Optimization

Together, the 3S program and D-Floc-It technology represent a comprehensive approach to mill optimization. By focusing on safety, support, success, and incorporating cutting-edge technology, ANDRITZ offers a holistic solution to the challenges faced by modern pulp and paper mills.

Conclusion

ANDRITZ’s combined introduction of the 3S program, and D-Floc-It technology marks a significant advancement in the industry. These initiatives provide mills with the tools needed for enhanced efficiency, reliability, and product quality. With a strong commitment to innovation and excellence, ANDRITZ is leading the way toward a more efficient, sustainable, and successful future for the pulp and paper industry.

For more information on the 3S program and D-Floc-It technology, contact ANDRITZ today. Together, we can achieve unprecedented levels of performance and success in the pulp and paper industry.