Infrared Thermal Smart Cameras

See Through Steam

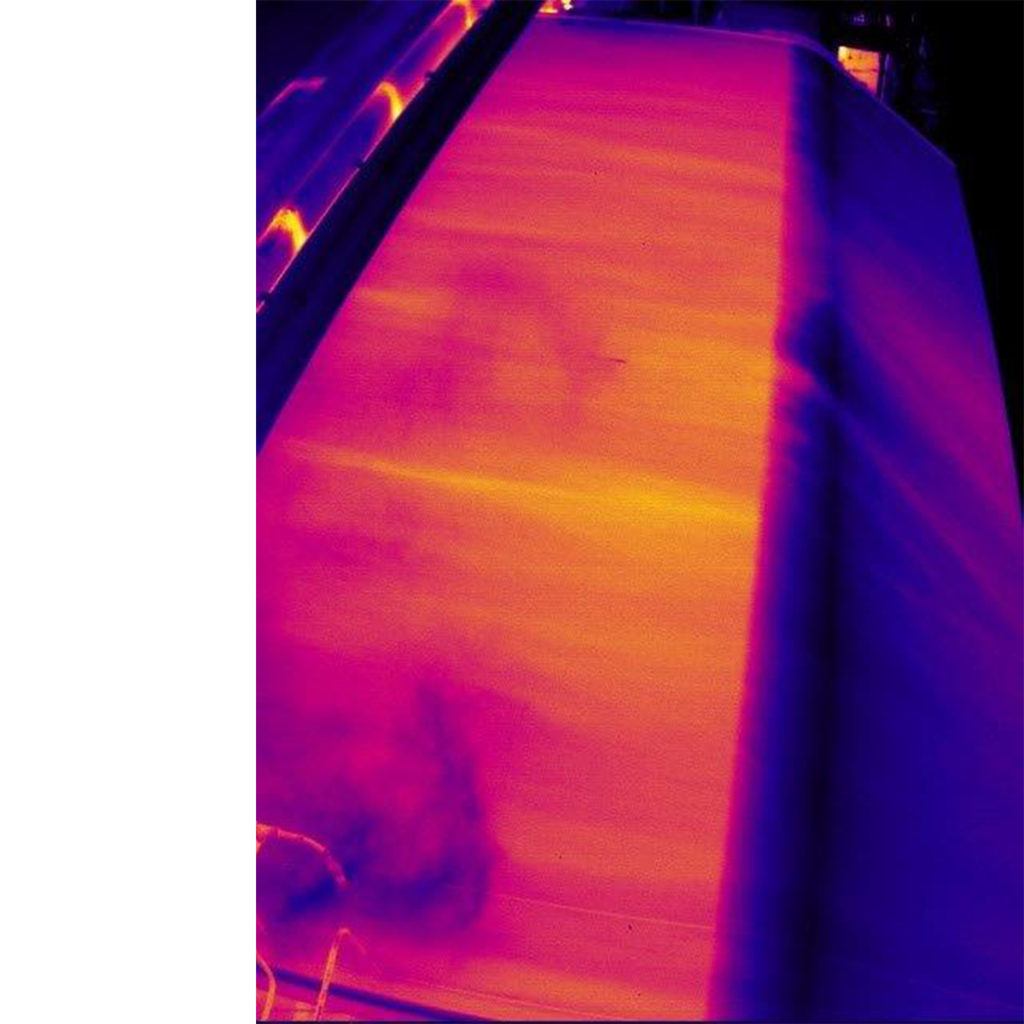

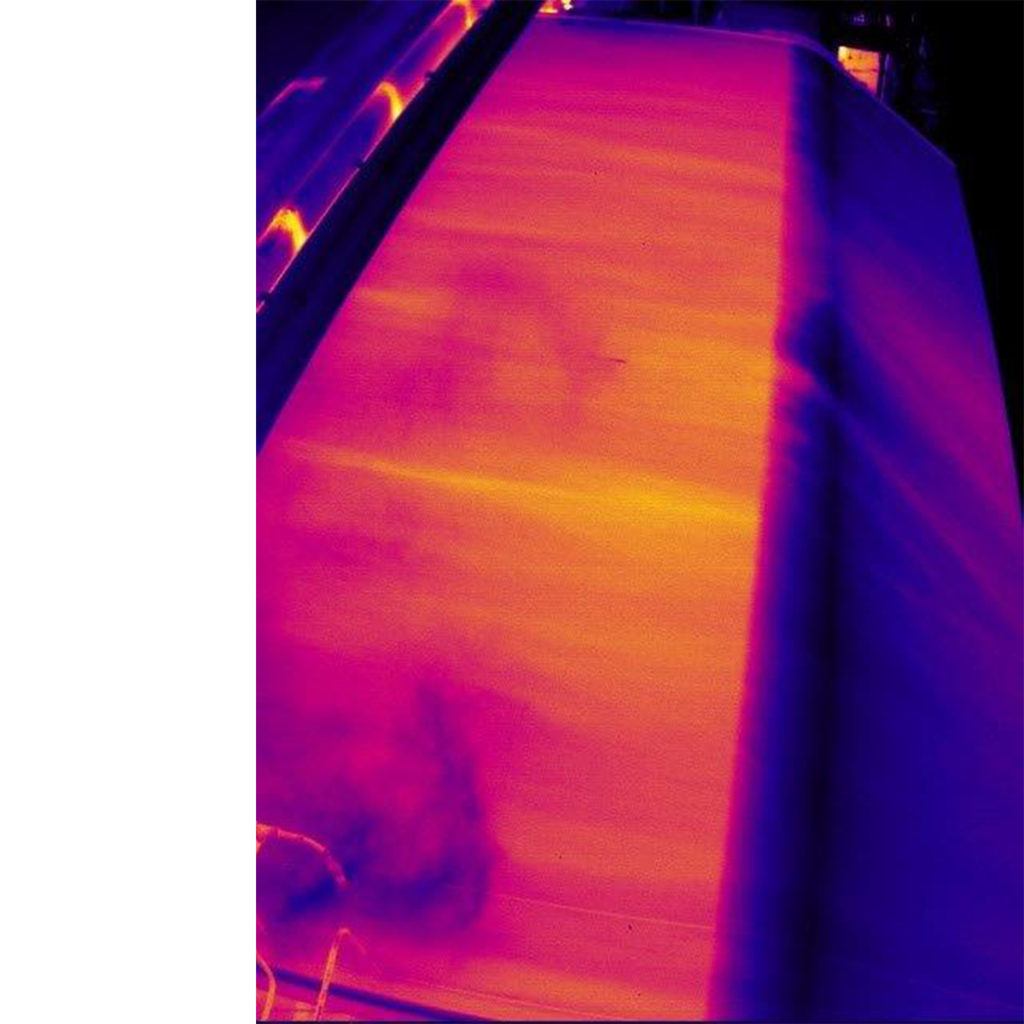

Trace defects through Steam with Procemex Infrared Camera Technology

Procemex Infrared Thermal Smart Camera provides visibility to trace defects in paper mill areas where it has not been possible in the past, especially those obstructed by steam and fog. The inrared cameras are especially suitable to areas where normal web monitoring cameras do not work because of steam. Procemex Infrared Thermal Cameras are the perfect solution.

Procemex Smart Cameras – Your Eyes In Production

Thermal imaging and inspection of the process provide next level troubleshooting capabilities.

- Game changing technology in identifying root cause with thermal imaging of felts, wires, rolls, and dryer cans

- Visual variation of temperature

- Wire condition analysis

- No lights needed

- Same easy connectivity like in all other Procemex SmartCameras too

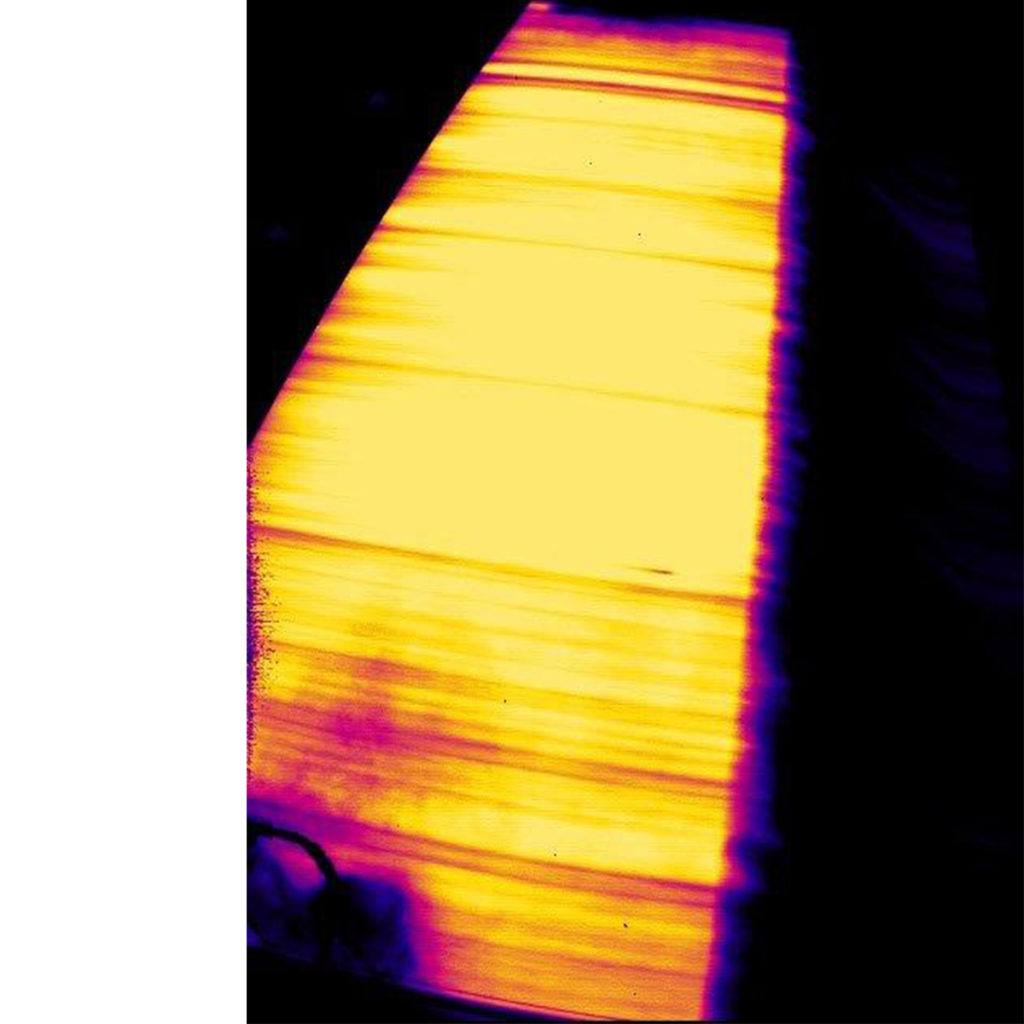

Reveal the Moisture and Dry Weight Profile issues

The fast high definition Flex Infrared Smart Camera detects and visualizes deviations in moisture profile in a continuous full-width view and provides constant online real-time feedback. The camera shows consistent, high resolution imaging of cross direction and machine direction moisture variations in the sheet, from wet end to the reel and everything in between.

Flex Infrared is a new tool for enhanced troubleshooting in the the paper making process with real-time thermal imaging of:

- Moisture Profile

- Paper Edge Profiles

- Dry Weight Profile

- Fabrics Analysis

- Roll Temperature Analysis

- Dryer Cylinder Temperature Analysis

- Yankee Temperature Analysis

Infrared Thermal Cameras can be easily integrated with Procemex OnePlatform System. Flex IR camera is also available as a standalone solution.

Infrared Thermal Camera – Easy Integration to Procemex OnePlatform

Future Proof Technology

The new addition to the Procemex OnePlatform family is built on the same, trusted SmartCamera platform and utilizes the same software and user interface for a seamless “plug and play” integration into existing Procemex OnePlatform solutions.

Procemex Infrared Thermal Smart Camera has an upgradeable image sensor card and a long lifetime with secured future compatibility (TCP/IP, future proof detachable sensor).

True Smart Cameras

Procemex Integrated Paper Web Monitoring and Web Inspection Solution is designed with the concept of utilizing different camera technologies under a single OnePlatform operating system. The Procemex OnePlatform system is a single interface that provides seamless integration for a variety of camera types. This allows the solutions to be customized to specific needs of the paper machine.

Procemex Infrared Camera Technology: Revealing Hidden Defects Amidst Steam

Procemex’s Infrared Thermal Smart Camera technology has revolutionized defect detection in paper mills, even in areas traditionally obscured by steam and fog. These innovative infrared cameras excel in environments where conventional web monitoring cameras struggle due to the presence of steam.

In paper mills, maintaining product quality and minimizing defects is paramount. However, the challenges posed by steam and fog in certain areas have historically hindered effective defect detection. Enter Procemex’s Infrared Thermal Smart Cameras, a game-changer in the industry.

These cameras utilize advanced infrared technology to pierce through the steam and fog, providing unparalleled visibility to trace defects that were once elusive. By doing so, they empower paper mills to take proactive measures to rectify issues, enhance product quality, and optimize production processes.

What sets Procemex’s Infrared Thermal Smart Cameras apart is their adaptability and effectiveness in steam-rich environments. They bring a new level of precision to defect detection, ensuring that even the most subtle issues are identified promptly. This not only improves product quality but also reduces waste and operational costs.

In summary, Procemex’s Infrared Camera Technology is a game-changer for paper mills. It overcomes the challenges posed by steam and fog, enabling mills to maintain product quality, streamline operations, and ensure customer satisfaction. With these cameras, the previously hidden defects are revealed, making the production process more efficient and reliable.