BENEFITS:

- Extra textile process speed up to 15%

- Lower CV% in weight variation

- Self-regulation of fiber mat (ProWin closed loop)

- Significant reduction of card and crosslapper acceleration during high-speed operation

Optimization of evenness of the material web, better distribution of fibers, and thus higher quality for better products are the basics of ANDRITZ systems for web profiling. Different systems are used depending on the application and the targeted products.

Closed loop self-adjustment

Once the weight profile distribution is displayed on the ANDRITZ gauge, the ProWin technology self-adjusts, how to build the fiber mat at the crosslapper stage, in cross direction as well as in machine direction, to anticipate the fiber mat deformation during the downstream bonding process.

Smooth operation

As an additional benefit, the ProWin balanced weight profiling correction technology contributes significantly towards reducing card and crosslapper acceleration during high-speed operation.

New ANDRITZ gauge

ProWin is coupled with the new ANDRITZ gauge (installed just before the end of the line), which handles the self-regulation (closed loop). It accurately controls the product regularity at the end of the line and automatically allows data analysis and processing by ProWin, consequently improving the end products’ CV% performance. The new ANDRITZ gauge is a key device for ProWin closed loop ANDRITZ lines.

Fiber saving

The ANDRITZ ProWin technology also contributes savings of up to 10% by eliminating superfluous fibers on the edges of the mat supplied. This saving provides a faster return on investment and lower OPEX thanks to ProWin.

Web profile with ProWin system

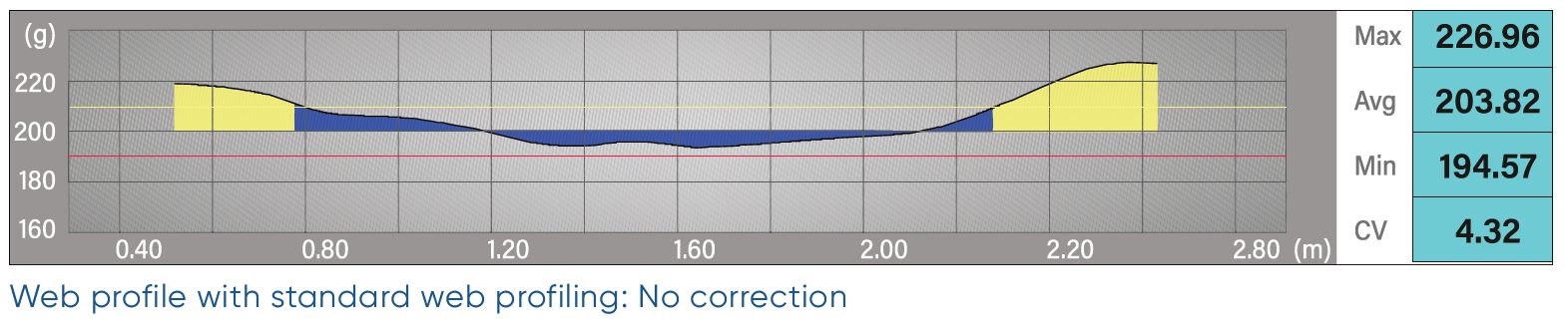

Web profile with standard profiling: No correction

ProWin action illustration

Our fully equipped technical center for needlepunch production is also available for ANDRITZ ProWin. Here you can see the amazing features of ProWin live and we will help you turn your product ideas into reality. On our Technical Center page you can directly send us a request for an appointment booking in our technical center.

ANDRITZ ProWin 3D animation showing effects on the processing

Senior expert J.C. Laune explains ANDRITZ ProWin

Integrated systems at crosslapper

ProWid™ is an innovative ANDRITZ technology allowing nonwoven producers to optimize the weight profiling capabilities at the crosslapper entry side. This ProWid is independent of the card type and so is also very good for crosslapper replacement in an existing line.

Improved coefficient of variation %

The ProWid system allows the carded web to be stretched to reduce its fiber weight so that the stretched web areas can be laid by the crosslapper on both edges of the fiber mat provided. Its closed loop design is an advantage in constantly improving the CV%.

Fiber saving

The ANDRITZ ProWid technology also contributes savings of up to 7% by eliminating superfluous fibers on the edges of the mat supplied. This saving provides a faster return on investment and lower OPEX thanks to ProWid.

Web profile with ProWid system: Dynamic web profile correction

Impact of the ProWid system on fiber distribution