ADMOS - Pass Schedule Optimization and Flatness Precalculation

ADMOS - ADvanced Mill Optimization System is the name of the completely new development of pass schedule optimization and flatness precalculation within the level 2 automation system from ANDRITZ Metals Germany for cold rolling mills.

On the one hand, it was developed with the aim of calculating the rolling forces and torques and the occurring heating of the strip based on the latest complex technological models in order to determine the optimum pass schedule, and on the other hand, to ensures the best possible product quality by integrating a discretized model for flatness precalculation.

Models

As a basis for the calculation, models are used to calculate the

- Yield Stress (temperature dependence is included)

- Tension (complex mills with multiple reels and S Bridles can be easily created)

- State-of-the-art models for roll force and moment calculation

- Analytic model for calculation of roll force and torque

- Elasto-plastic strip behavior for improved calculation results especially for foils

- Advanced Friction model for consideration of rolling speed

- Strip / Roll Temperature Calculation

- Preset Calculation with a Discretized model for each type of mill stand with support of the following flatness actuators

- Continuously Adjustable Crown (CAC)

- Taper Roll Shifting (TRS)

- Roll bending

- Yield Stress Adaptation with consideration of

- Short term adaptation within the coil

- Long term adaptation over larger number of coils

Scope of services

ADMOS is available in various configurations provides the following functionalities (depending on the configuration)

- Pass schedule calculation and optimization

- Individual parameter sets for different products

- Adaption of yield stress curves and friction values

- Flatness precalculation for the entire pass schedules to improve the preset settings of the flatness actuators

- Pre-calculations of pass schedules of new products

Application

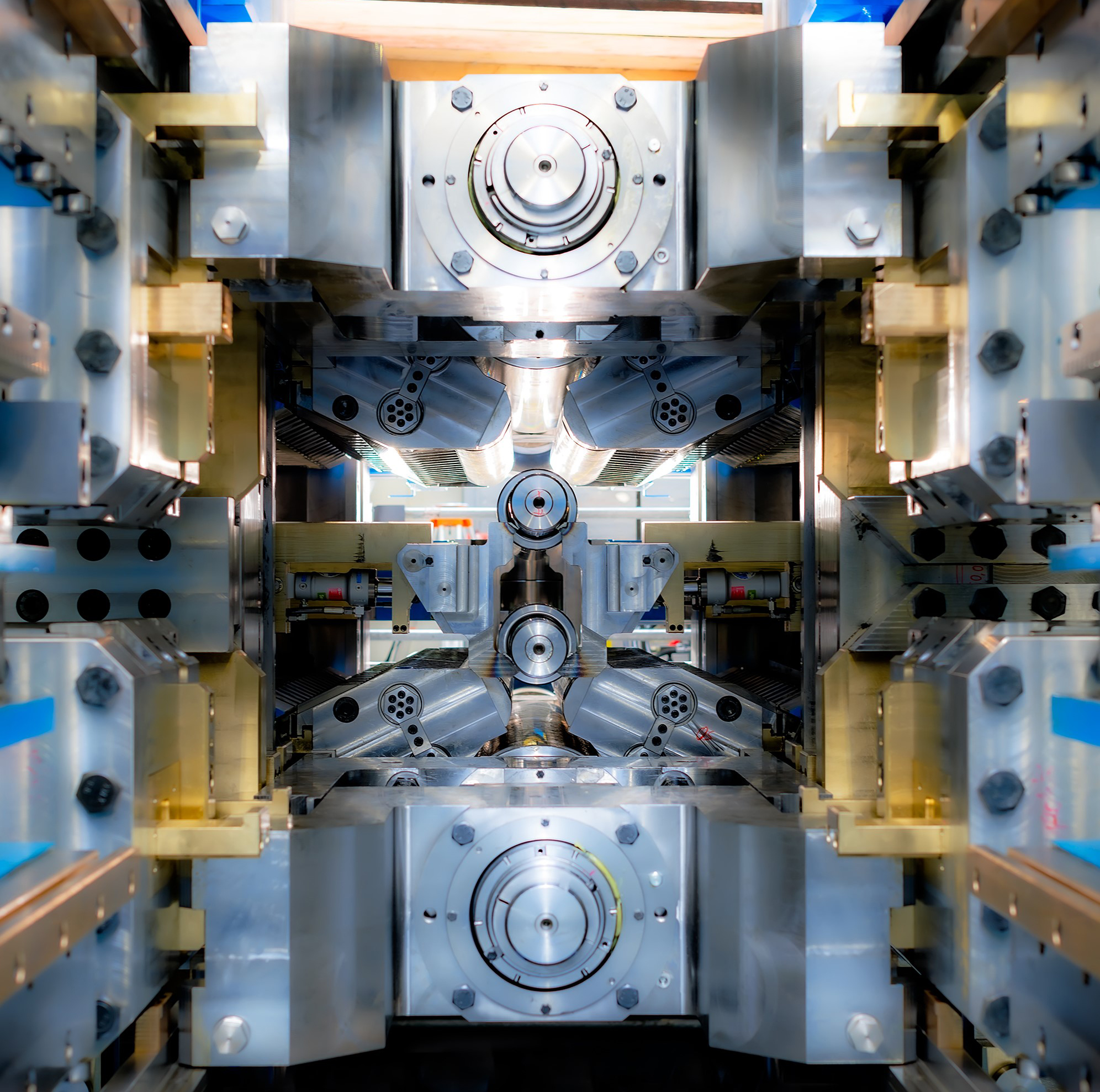

ADMOS can be used for any type of mill, from a reversing stand to a tandem stand roll stand and supports many types of roll stands

- 2-High

- 4-High

- 6-High

- S6-High

- 20-High

It can be installed at new plants as well as it can be used for revamps of existing plants.

Your Benefits

This superb technical solution ensures a precise roll force calculation with deviation of less than 5 % (assuming adapted steel grade) and enables

- Fewer passes required for a large number of calculated pass schedules due to better utilization of the maximum possible rolling force

⇒ Higher throughput

- Better flatness due to more uniform rolling force curves

⇒ Improved product quality

Precise strip temperature calculation with deviation of less than 10 °C (assuming calibrated system) enables

- Better achievement of desired temperatures

⇒ Improved product quality

- Cooling Amount Optimization enables precisely matching amounts

⇒ Reduced costs for reprocessing