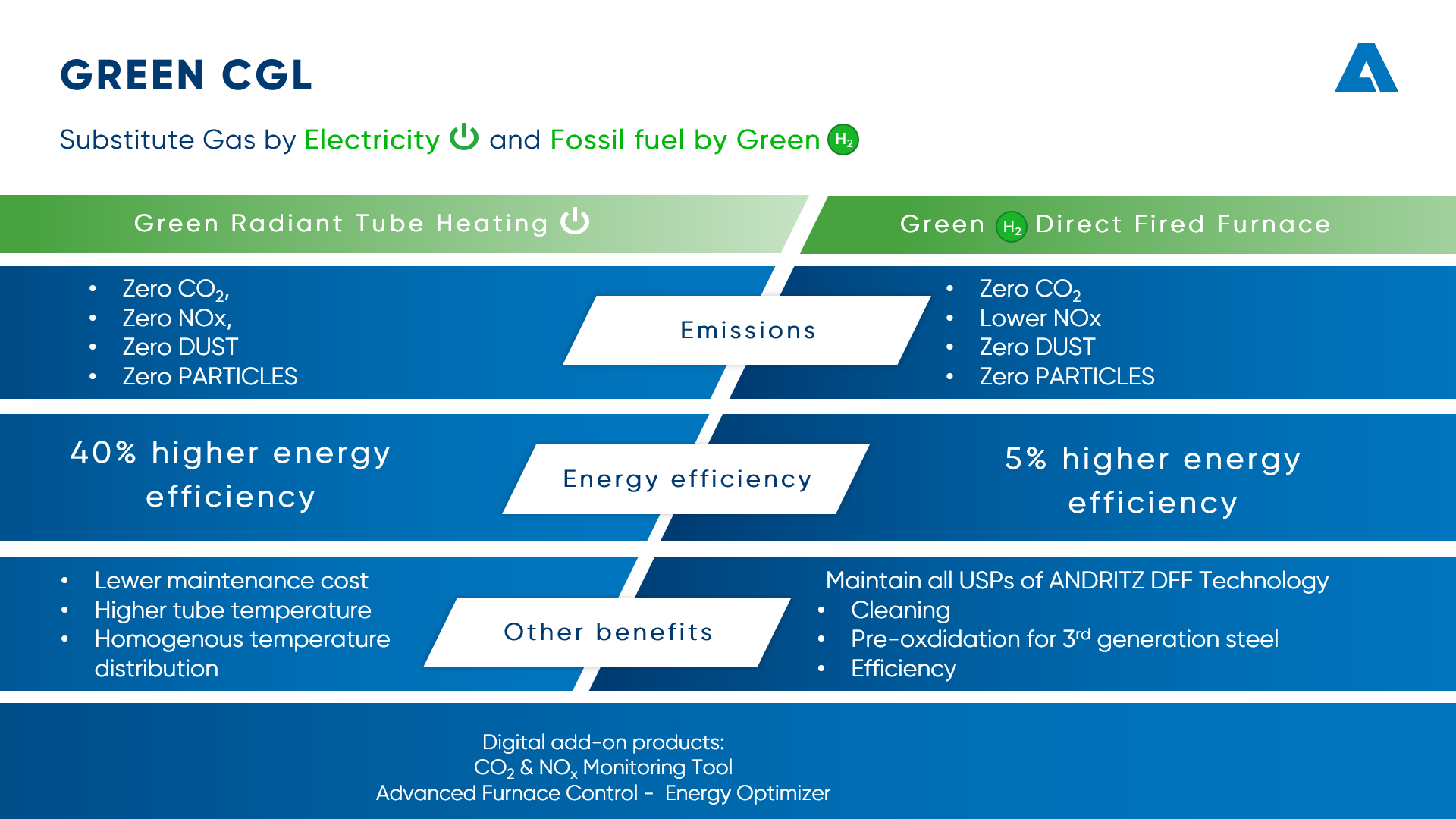

OUR OFFERING: A CGL WITH NO CO2 EMISSIONS

A typical continuous galvanizing line (CGL), producing around 550,000 tons of steel, emits 32,000 tons of CO2 per year through gas-fired heating sections. Our vision for the future is to achieve a CGL with zero CO2 emissions by using renewable electricity and green hydrogen.

We have now developed a unique solution to replace the CGL’s gas-fired radiant tubes with electrical ones – without having to modify the existing support or inner furnace. This allows fast revamps and simplified maintenance. By using renewable electricity, local CO2 emissions can be eliminated completely. In addition, toxic NOx emissions are removed and energy efficiency can be increased by up to 40%.

To test the mechanical solutions in real operating conditions we have designed and built a furnace in our laboratory in Hemer, Germany. We have also successfully validated our pioneering solution in customer furnaces.

Exemplary radiant tube setup in our test furnace in Hemer: