Needlepunch for sustainable products

ANDRITZ also offers its innovative and sophisticated needlepunch technology for production with natural or recycled textile fibers or a combination of different fiber types

ANDRITZ offers needlepunch solutions using 100% recycled fibers for the production of numerous material applications for the construction industry, the automotive sector, technical felts, carpets and many more. This makes the products particularly sustainable and not a bit inferior in quality to using virgin fibers.

More sustainability in needlepunched roll goods

Drylaid nonwoven systems such as needlepunch with opening and blending equipment can handle all kinds of staple fibers, depending on the end application. This is what makes them so versatile. And of course, recycled fibers, e.g. from textiles, can also be used, as well as natural fibers, e.g. from the shank or leaves of certain plant varieties. Numerous durable applications require special properties such as robustness, durability and dirt repellency, such as car interiors, carpeting or wall reinforcements. Others need to be particularly bulky and air-permeable, but also thermally and acoustically insulating, such as insulation materials for house construction.

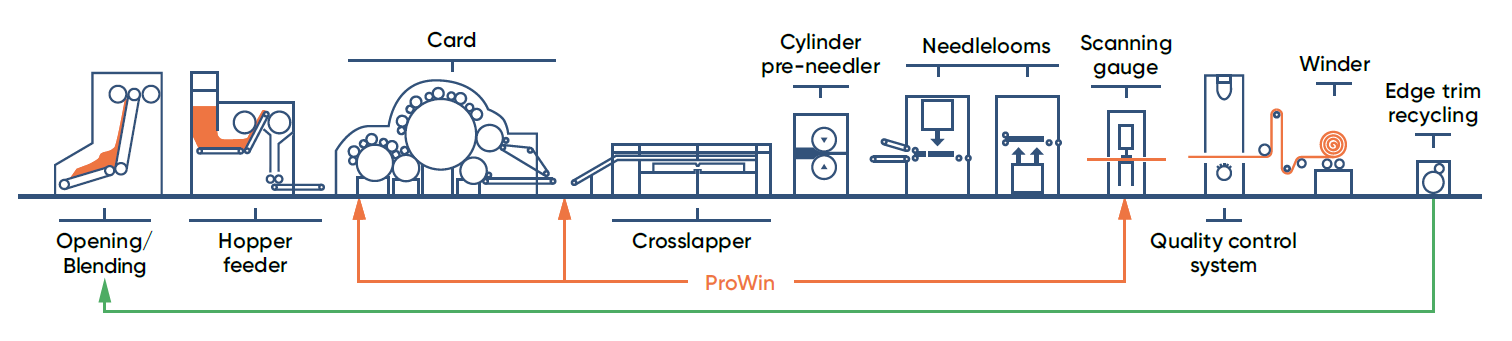

Sample 2D configuration of the needlepunch line for technical felts

Textile Recycling inhouse

Recycled fibers can certainly be an alternative when it comes to the production of numerous materials from needlepunch production. ANDRITZ offers complete systems for textile recycling, also for in-house operation by needlepunch producers. The ANDRITZ Cadette line is ideal in terms of capacity for in-house production of recycled textile fibers.

Our technical center supports you

The ANDRITZ Technical Center for Needlepunch is a comprehensive testing facility for all kinds of product tests. With all necessary machines and a laboratory for detailed analysis of your tests. The team of experts on site is looking forward to your inquiry on how we can help you make your nonwoven production more sustainable.