Biomass powder burning: A profitable switch to replace fossil fuels in the lime kiln

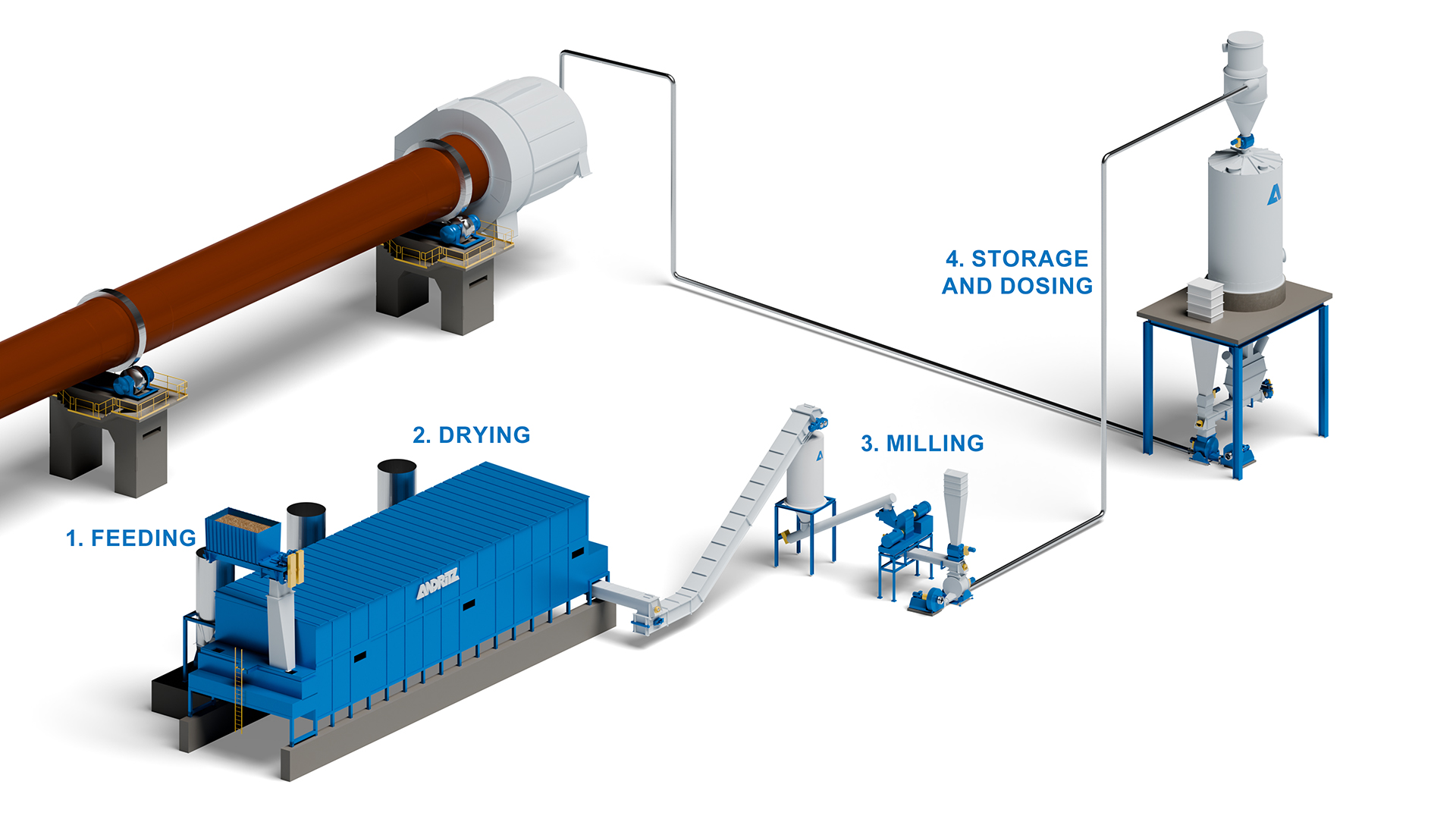

ANDRITZ LimeBio-Powder biofuel plant to replacing fossil fuels in the lime kiln is technically easy to adapt, easy and reliable to operate, and financially appealing.

The switch from fossil fuels to biomass powder burning in lime kilns is now easier and more efficient than ever. ANDRITZ’s LimeBio-Powder biofuel plant gives pulp mills an opportunity to fire the lime kiln with renewable fuel sources in a simple, automated process. With the powdering technology, the existing sources of biomass can be utilized to replace the usage of fossil fuels ꟷ wood powder is just one of the biomass types that can be used. The concept is straightforward to meet ever-growing defossilization demands. The ANDRITZ biomass powder burning solution far exceeds any other technology on the market when it comes to quality output, energy costs, and ease of maintenance.

Easy adaptation into existing lime kilns

The ANDRITZ LimeBio-Powder biofuel plant is designed for seamless integration with current lime kiln operations, ensuring minimal disruption and maximum efficiency.

- Easy to install, can be situated anywhere around the mill

- Operating is similar to fossil fuel feeding systems, which means there is no steep learning curve for the operators

- Fully autonomous operation possible

- Can be implemented to any DCS systems or ANDRITZ automation and digitalization solutions

- Fine particle size for an efficient combustion and correct temperature profile in the lime kiln.

Efficient and financially beneficial fueling of the lime kiln

Switching to biomass powder burning not only reduces energy costs but also offers a quick return on investment, making it a financially sound choice for pulp mills.

- Technology that enables quick defossilization of the lime kiln

- Small footprint

- Fast processing time

- Consumes remarkably less energy per refined tons of biomass than with previous technology

- Low maintenance demand through powder quality

- Short return of investment.

Many kinds of biomass can be utilized as fuel in the lime kiln

The ANDRITZ LimeBio-Powder enables the use of biomass that can be moist or dry and still gain the fine powder result. It has the smoothest feeding and stable burning in the lime kiln. Biomass of different shapes and sizes that can be used include:

- Mill and forest residues

- Wood waste

- Pellets.

ANDRITZ LimeBio-Powder is a powdering-based lime kiln biofuel plant