Biomass powder burning is much more efficient than you might think

The switch from fossil fuels to biomass burning in lime kilns has now been made easier than ever. ANDRITZ’s refining technology gives pulp mills an opportunity to fire the lime kiln with renewable fuels in a simple, ultra-efficient, automated process.

Some pulp mills are already using biomass as a fuel for lime kilns utilizing “hammer” type technology for powdering biomass. In these systems, biomass is hammered several times to reach the required particle size. This process takes time and uses a lot of energy.

This means fast processing time, low energy consumption, and low maintenance demand. “All in all, the possibilities we offer, really are attractive for pulp mills,” adds Seppänen.

HIGH EFFICIENCY FROM THE REFINING TECHNOLOGY

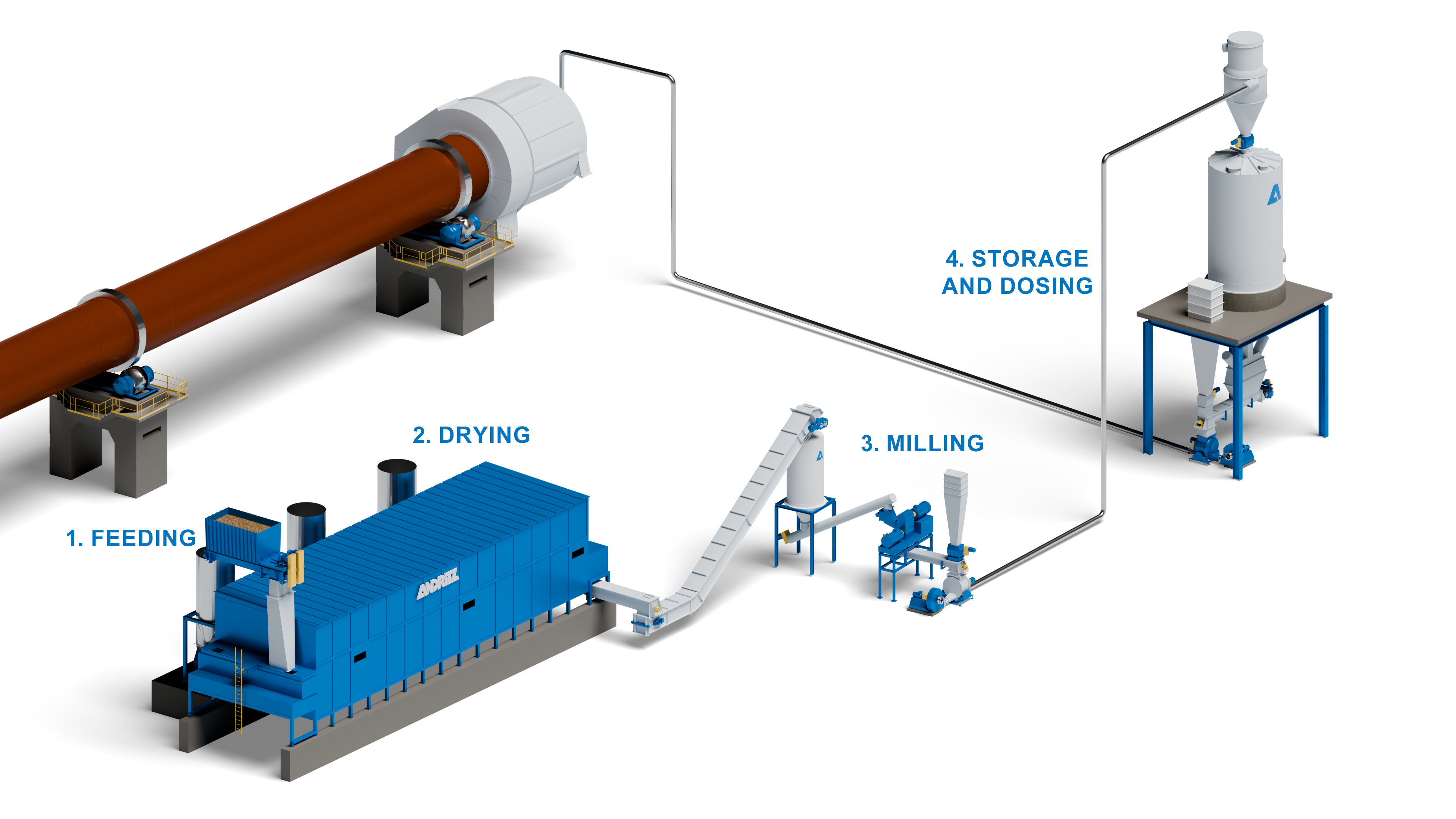

The powdering process includes refining the wood-based biomass for example pellets, sawdust, and wood residues from the mill or the mechanical wood industry and refining it into highly combustible powder, perfectly suitable for fueling the lime kiln.

“High efficiency comes from the rapid burning of the powder and steady temperature profile inside the kiln. This results from the exact and consistent particle size of the powder”, says Seppänen. “Our system is designed to ensure the quality of the powderizing does not vary over time and is stable and reliable in the long term.”

Highly combustible powder, perfectly suitable for fueling the lime kiln

Another essential issue is the steady and optimal dosing of the powder into the lime kiln.

“We provide our customers with a highly automated and accurate dosing system for the best operating efficiency,” adds Seppänen.

The powdering technology ANDRITZ utilizes is one of the most trusted refiner technologies available. It is widely used in energy generation and asphalt production. ANDRITZ has specifically developed the technology for effective use at pulp mills.

FULLY AUTOMATED OPERATION

The system operates automatically with the biomass being transported into the refiner via dosing screws. Seppänen explains the process, “The biomass is fed to the refiner via a screw system and carried to the silo via a screw feeder. The powder is fed to the lime kiln via a dosing system and then blown into the burner.”

ANDRITZ LimeBio-Powder is a powdering-based lime kiln biofuel plant

“The LimeBio-Powder system is very simple to operate. It doesn’t differ much from the way a fossil fuel fed systems work, and there is no steep learning curve involved,” says Seppänen. “The fully automated system can be connected to the mill’s DCS system or ANDRITZ automation and digitalization solutions for data gathering and management.”

In terms of installation, the system can be easily located close to the lime kiln. However, it can be situated anywhere around the mill as ANDRITZ can easily adapt the ancillary equipment including pipes and a pneumatic transfer device for the system to successfully operate.

Seppänen concludes, “With our biomass powder burning technology for the lime kiln, pulp mill operators have the opportunity to quickly and easily switch from burning fossil fuels to a much more environmentally friendly fuel.

“The switch from fossil fuels into biomass powder burning in lime kilns reduces carbon footprint, includes major savings on CO₂ per ton emission penalties, costs and volatility of fossil fuel supplies, and increased uptime due to less maintenance requirements.”