Biomass powder burning

ANDRITZ biomass powder burning: A financially appealing solution to meet ever-growing defossilization demands

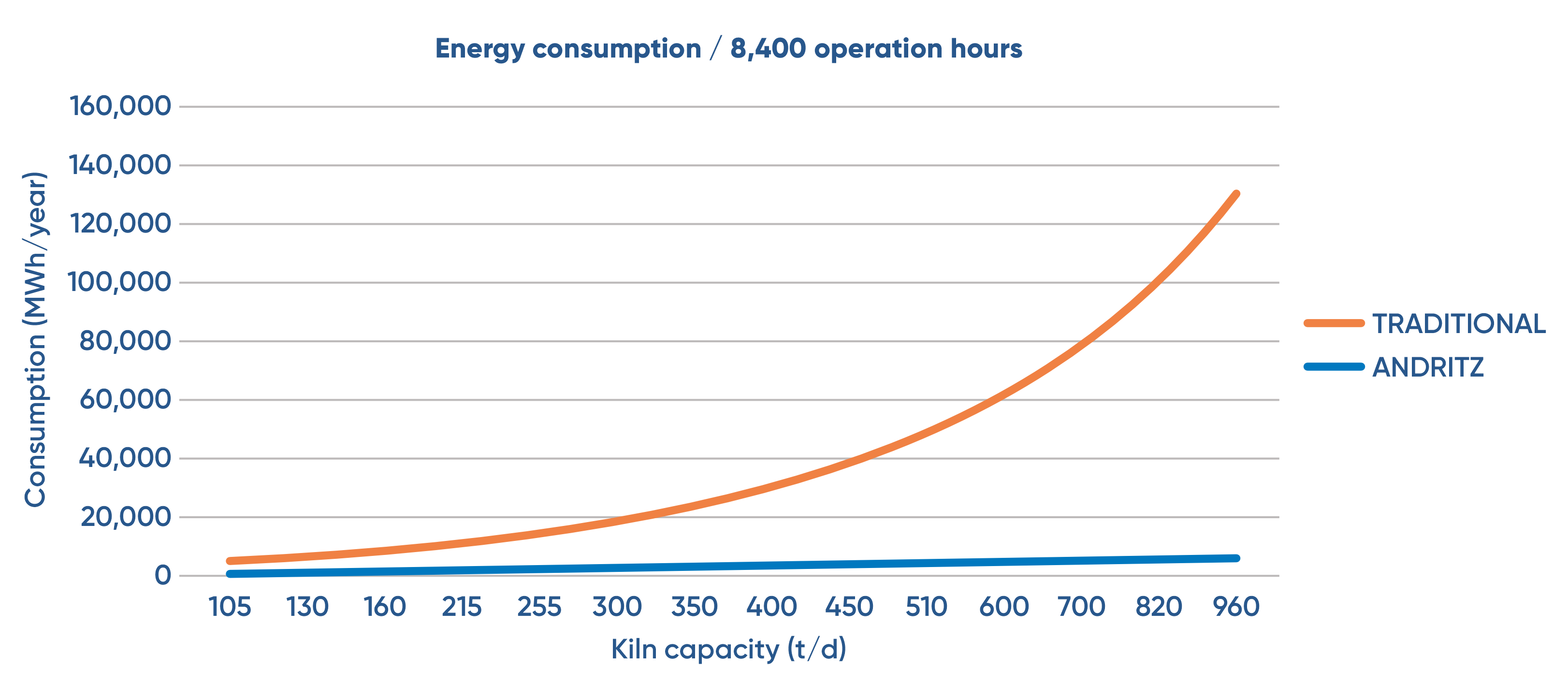

ANDRITZ´s biomass powder burning solution saves at least 50% more energy than other solutions available on the market with the return on investment being only 1ꟷ2 years. The solution derives from the commitment to accelerate the defossilization of the pulp industry.

The ANDRITZ LimeBio-Powder lime kiln biofuel plant uses a refining technology which utilizes a high-quality and precise cutting system. This results in a very consistent powder size and stable burning temperature. It uses at least 50% less energy when compared to the other solutions available.

Furthermore, the powdering system from ANDRITZ requires a lot less maintenance. Vuorela explains, “Our system can achieve over 3,500 operation hours before any blade sharpening. The rotor blades can be sharpened up to six times and sharpening can be carried out at the mill. The overall maintenance of the system has been made very simple with a maximum stop time of just two hours.”

IMMEDIATE SIGNIFICANT SAVINGS

In the highly competitive world of pulp production, there is a growing emphasis for producers to install the very best, cost-effective technology at pulp mills. This is just what ANDRITZ can offer to its customers with the LimeBio-Powder lime kiln biofuel plant. With the high efficiency, low maintenance costs and reduction in CO2 emissions by reducing fossil fuel usage, the return on investment can be just 1-2 years.

One thing is certain, carbon emission penalties will increase, and environmental regulations will tighten, not only in the EU but all over the globe. Now it is time to check all possible ways to reduce carbon emissions and find solutions that fit easily into the current mill layout and technologies.

“With our system, customers can be assured that they not only have a solution to deal with increasing carbon taxes, but also have a system that far exceeds any other technology on the market when it comes to quality output, energy costs, and ease of maintenance,” says Jari Vuorela, Product Manager at ANDRITZ.

PROVEN TECHNOLOGY FROM A QUALITY PRODUCT BASE

The disc-cutting technology ANDRITZ utilizes for its powder burning solution is specifically adapted to the needs of pulp mills and biomass processing. This well-established powdering technology is already proven and successfully used in various industrial areas, such as energy generation. It is one of the most trusted refining technologies available.

The LimeBio-Powder solution stems from ANDRITZ´s passion for innovation and commitment to finding ways to elevate customers' businesses to the next level. It also demonstrates ANDRITZ´s expertise in implementing cross-technology solutions.

“With a long history of supplying white liquor plants and producing a wide range of solutions for pulp mills, our company is the global market leader in plants, automation solutions, and services for the pulp and paper industry. Our biomass refiner solution is part of this widely used and trusted product family,” Vuorela concludes.

Alongside the LimeBio-Powder lime kiln biofuel plant, ANDRITZ also supplies gasification technology for the firing of the lime kiln, thereby providing a choice of solutions to achieve defossilization goals. Whatever the mill set up, we can assist in the selection of the very best solution that suits our customers’ environmental, financial and production goals.