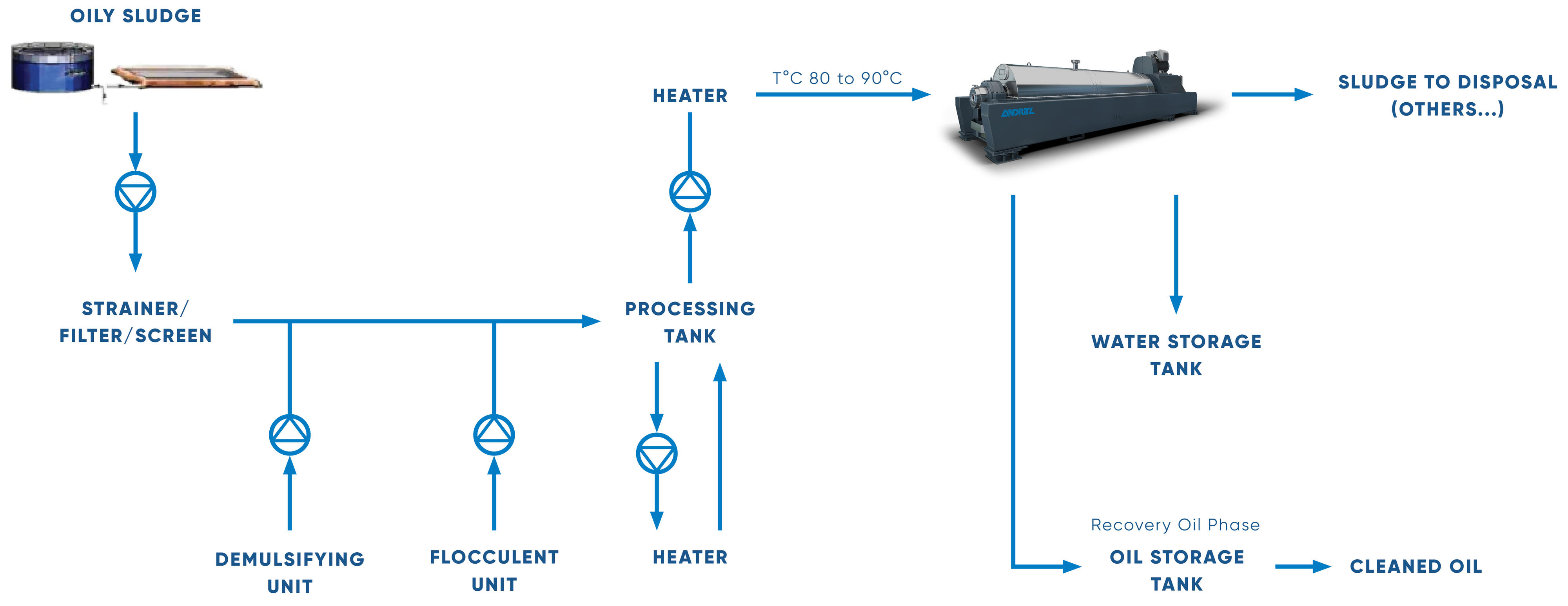

Issues with the disposal of oily sludge? Or simply eager to turn waste to value? Drawing from a vast experience of over 30.000 references since 1920, ANDRITZ has customized a 3-phase decanter centrifuge to reduce waste and increase profits – by efficiently recovering industrial oil. A robust design and special energy-saving features make them suitable for recovering multiple kinds of oil in a vast variety of environments – even including ATEX ZONES 1 and 2 and toxic environments. The decanter is now available as single machine, skid, or complete plant.