DON'T MISS OUT ON THESE BENEFITS:

- Designed to last thanks to profound process and operating know how, based on 60+ years of experience

- Maximum uptime and easy maintenance with the express cartridge

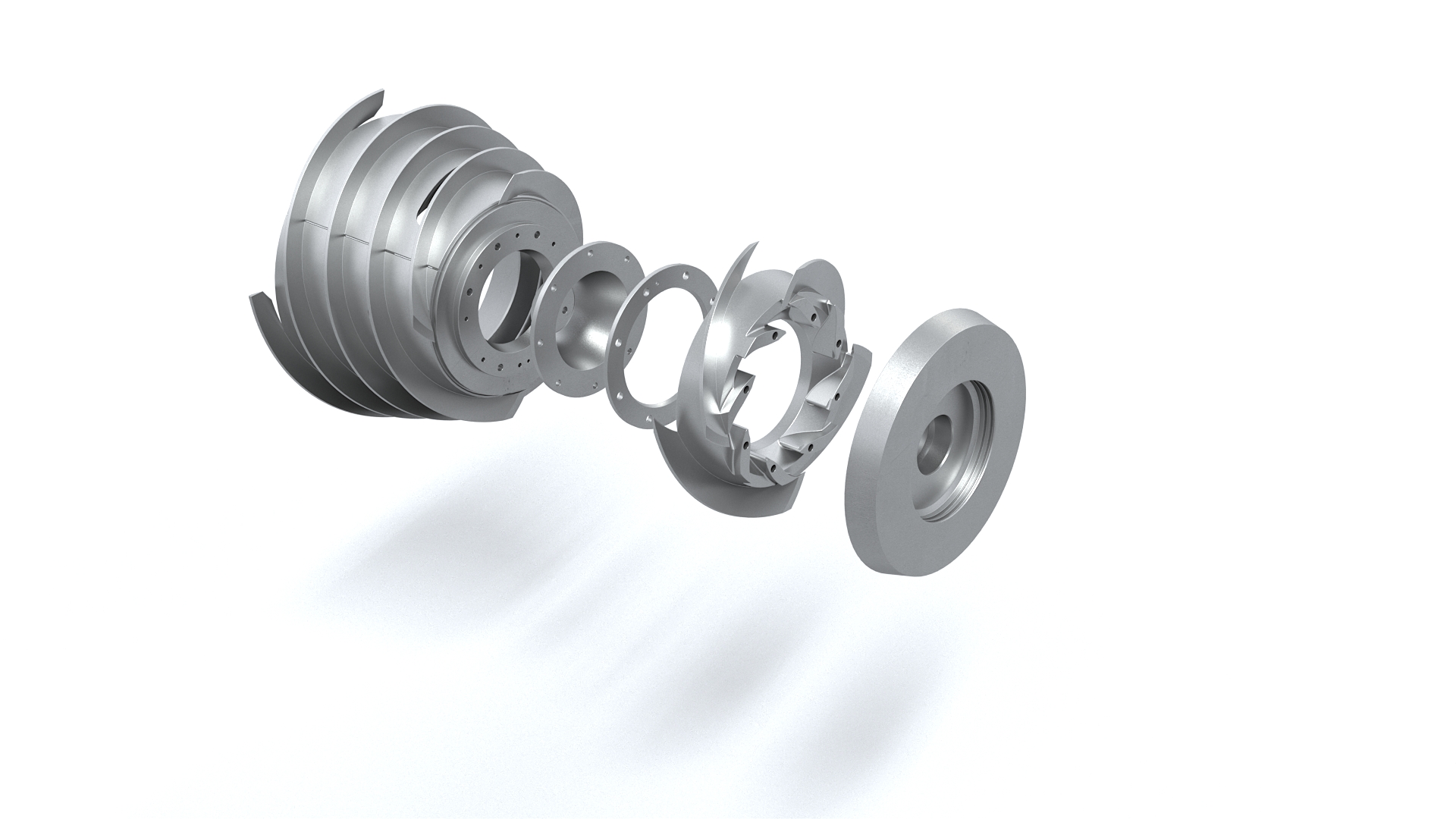

- Convenient and efficient maintenance as a result of the patented and modular scroll design

- Reduced wear and particle attrition enabled by the Gentle FeederTM feeding system