Are you ready to be a pioneer in advanced biofuels?

ANDRITZ has developed a concept for the large-scale production of advanced biofuels with clear market potential and business opportunities. The well-recognized gasification concept allows for simple, lower pre-fuel treatment cost with a high technical readiness for scaling up production. These plants will be first-of-a-kind and will represent a pioneering activity in the renewable fuels market.

ANDRITZ is a full scope and vastly experienced supplier of gasification technology. Jean Taillon, Director, Business Development for Gasification at ANDRITZ, says, “We’re proud of our expertise in biomass gasification, which integrates well with our long and recognized presence in the global wood pulping industry. Combining our in-house technologies with selected partners for other complementing areas gives ANDRITZ a unique understanding of the technological processes, market conditions as well as capex evaluations.”

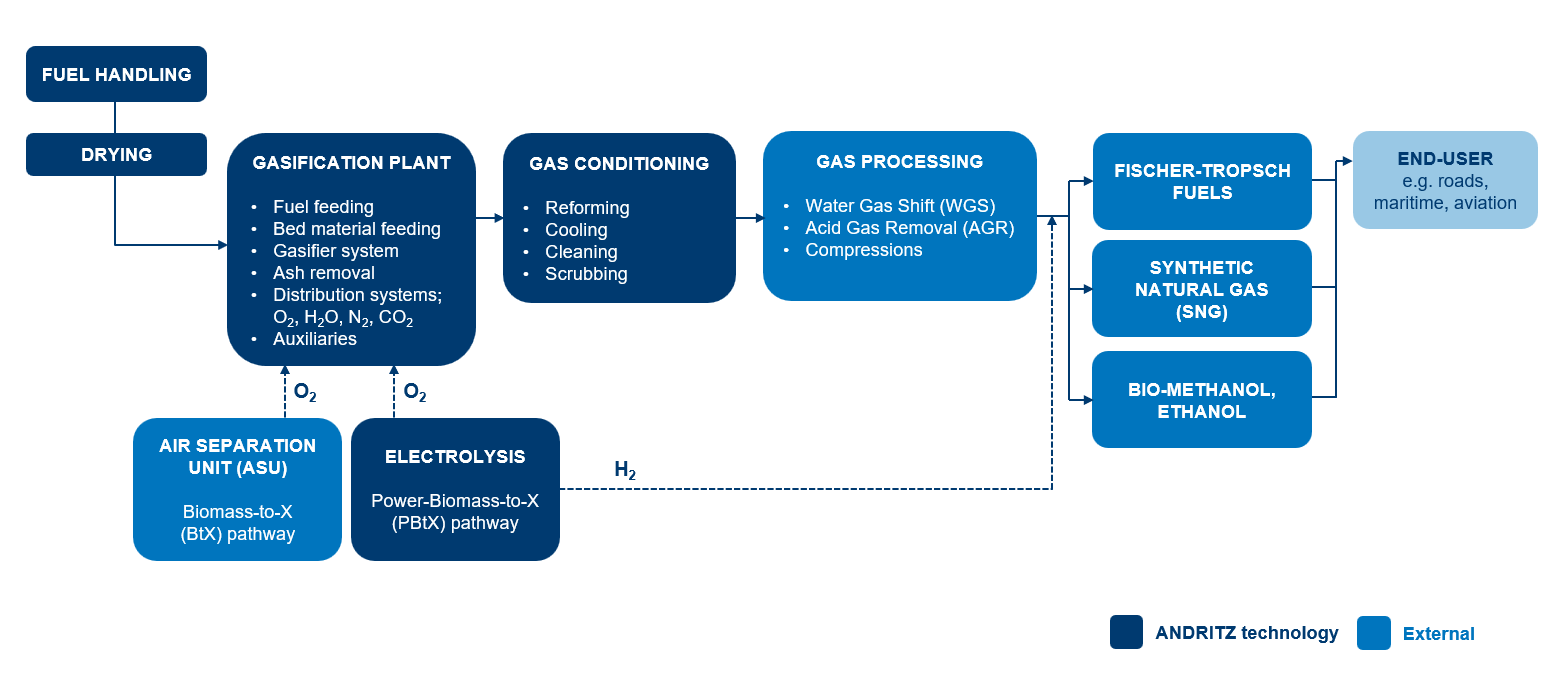

The technical process of advanced biofuels is complex, so here is an overview of the steps involved in transforming wood-based biomass into advanced biofuels, showcasing the gasification technology.

Getting technical: Advanced biofuels process in a nutshell

Gasification process for advanced biofuels

Feedstock pre-treatment: The process begins with the reception, handling, and pre-treatment of wood-based biomass, which includes crushing to achieve suitable particle size and drying to reach the required moisture level.

Gasification principle: Fuel is fed into a reactor under pressurized sub-stoichiometric conditions, transforming it into gases such as hydrogen, carbon monoxide, methane, and carbon dioxide. This raw gas is then reformed in a partial oxidation system (POX) to convert tars, methane, hydrocarbons, and unburned carbon into carbon oxides, hydrogen, and water.

Gas cleaning: After the POX system, the gas is cooled and cleaned in a gas cooler and water scrubber. The gas cooler generates steam, part of which is used in the plant.

Synthesis: The clean syngas is processed to achieve the optimal H2 to CO ratio and then sent to the synthesis plant for final transformation into advanced biofuel.

Electrolysis and carbon yield: To increase the biomass carbon yield, additional hydrogen can be produced by water electrolysis working in parallel with the gasification plant.