Eva Boog

Head of Process & Product Management | Single Presses and Laser Solutions

Schuler-Platz 1, 73033 Göppingen, Germany

phone: +49 751 401-2004

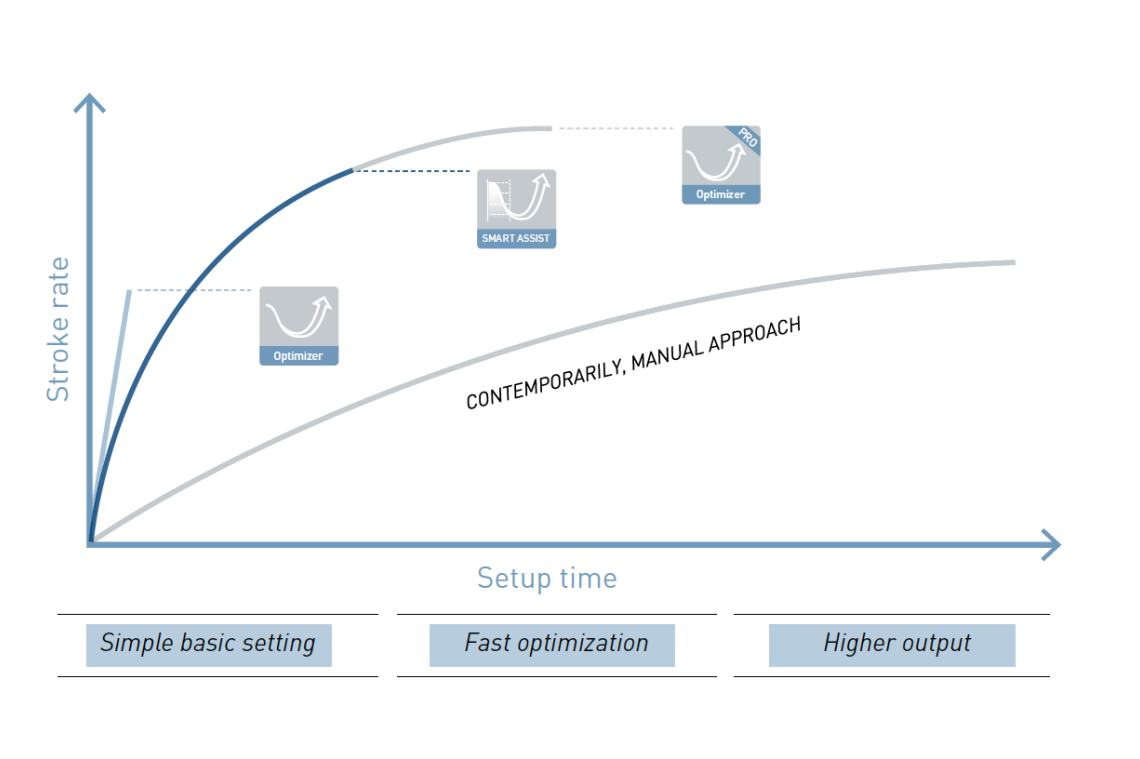

Setting up an entire system to handle new dies can be a very long and complex process, even for experienced setup engineers and system operators. But there can be an easier and more efficient way. The Metris Smart Assist from ANDRITZ, is a software-supported help tool for setting up and optimizing your production process. The tool's self-explanatory and intuitive operation does not require trained personnel. The assistant walks you through the setup process step-by-step on the HMI or smart devices with the help of images and videos. During each step, data is recorded through direct entries or teach-in functions. The collected data is used for fully automatic optimization of the movement curves for the slide and transfer system. From the very first stroke, your machine will deliver optimal output. Basically, all that’s left for the operator to do is press the start button.

The Metris Smart Assist can additionally be retrofitted onto existing systems at any time, and also includes the OptimizerPRO. With the OptimizerPRO, you can program ANDRITZ systems as needed with all degrees of freedom.

The fully automatic optimization of movement curves, including acceleration and setting angles, increases the production rate. And setup is finished in no time at all.

Thanks to the simple and intuitive operation, even inexperienced operators and setup engineers can set up and optimize dies in no time at all using the Metris Smart Assist.

For the real pros, the OptimizerPRO allows the movement curves for the slide and transfer system to be freely programmed. This means that even the last few percentage values of added performance, can be finessed out of the system to get the maximum output rate from the transfer press.

The Metris Smart Assist offers plenty of benefits including efficiency, effectiveness, and ease of use.

Benefits and features

Delivery

Head of Process & Product Management | Single Presses and Laser Solutions

Schuler-Platz 1, 73033 Göppingen, Germany

phone: +49 751 401-2004

Learn more about the Metris Digital Solutions of Metalsforming. We’d be happy to discuss your options for retrofitting individual functions and are here to help you on your path to a digital future.