Dr. Robert Vollmer

Manager Digital Automotive Solutions

Schuler-Platz 1, 73033 Göppingen, Germany

phone: +49 7161 66-3285

What if each of your parts could tell you its entire story, starting with the coil and ending with the finished part in detail? Some would explain to you why they were not formed because they had already been sorted out as blanks because they did not meet the material specification. Others, again, would show you how they became good parts by special adjustment of the machine parameters.

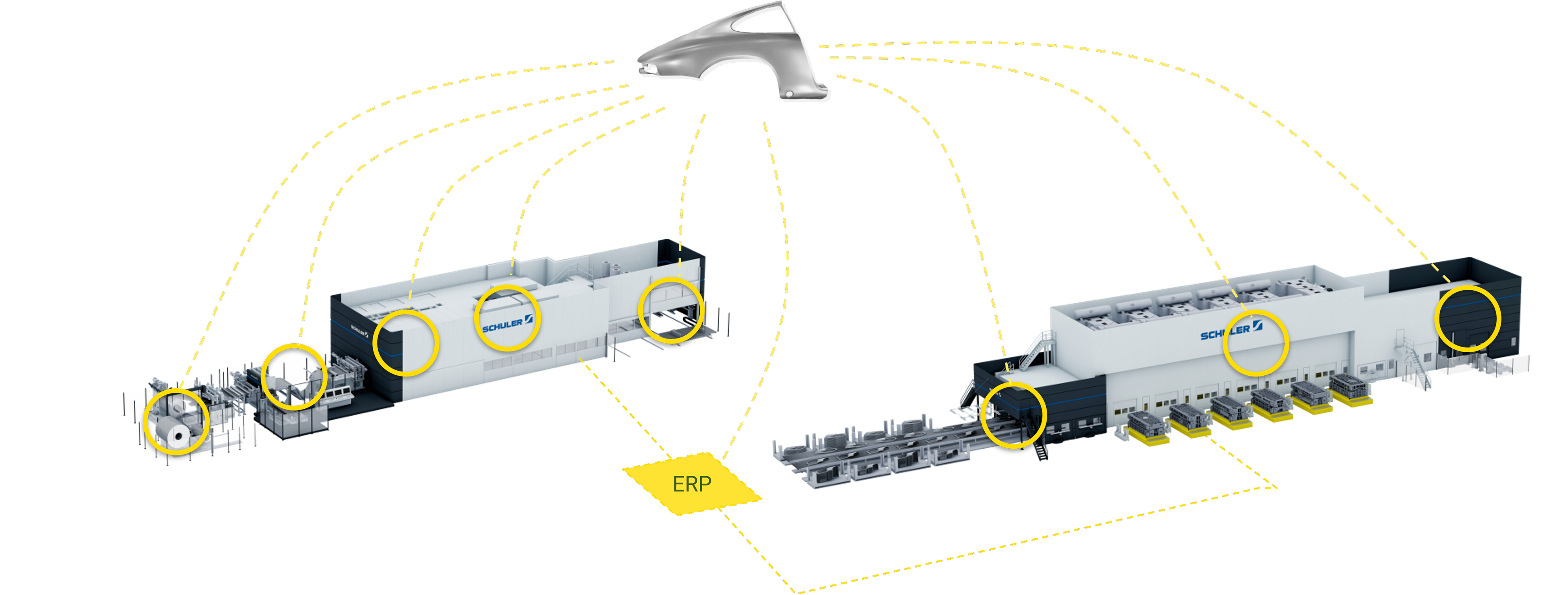

Metris Track and Trace links data and information to the component. The system marks each part with its own ID, which can be read out again. All important information on this ID is stored in a database. In this way, it is possible to subsequently check which coil the component came from, which parameters were present during the forming process, and which quality characteristics it has. Metris Track and Trace has direct access to the line control and thus to a large number of parameters.

Causes of defects can be identified as soon as possible to minimize scrap, prevent plant malfunctions and increase your productivity.

As material prices rise and qualities fluctuate, the investment in track and trace pays for itself within a very short time. In addition, you can document your production without gaps.

Blanking Line

Pressline

Convince yourself of the advantages of Metris Track and Trace:

End-to-end, plant-wide solution for the press shop from coil to finished part

Increase of the overall equipment effectiveness

Increase in part quality and reduction of scrap

Defects are identified fast and precisely

Target-oriented actions for defect prevention

Full connectivity to customer ERP/MES

Open data interfaces to customer analytics or AI solutions

Closed control loops possible through bidirectional communication between machines and track and trace

Manager Digital Automotive Solutions

Schuler-Platz 1, 73033 Göppingen, Germany

phone: +49 7161 66-3285

Vice President of Automotive Sales

Schuler-Platz 1, 73033 Göppingen, Germany

phone: +49 7161 66-996

Learn more about the Metris Digital Solutions of Metalsforming. We’d be happy to discuss your options for retrofitting individual functions and are here to help you on your path to a digital future.