Decades of expertise in lithium mining

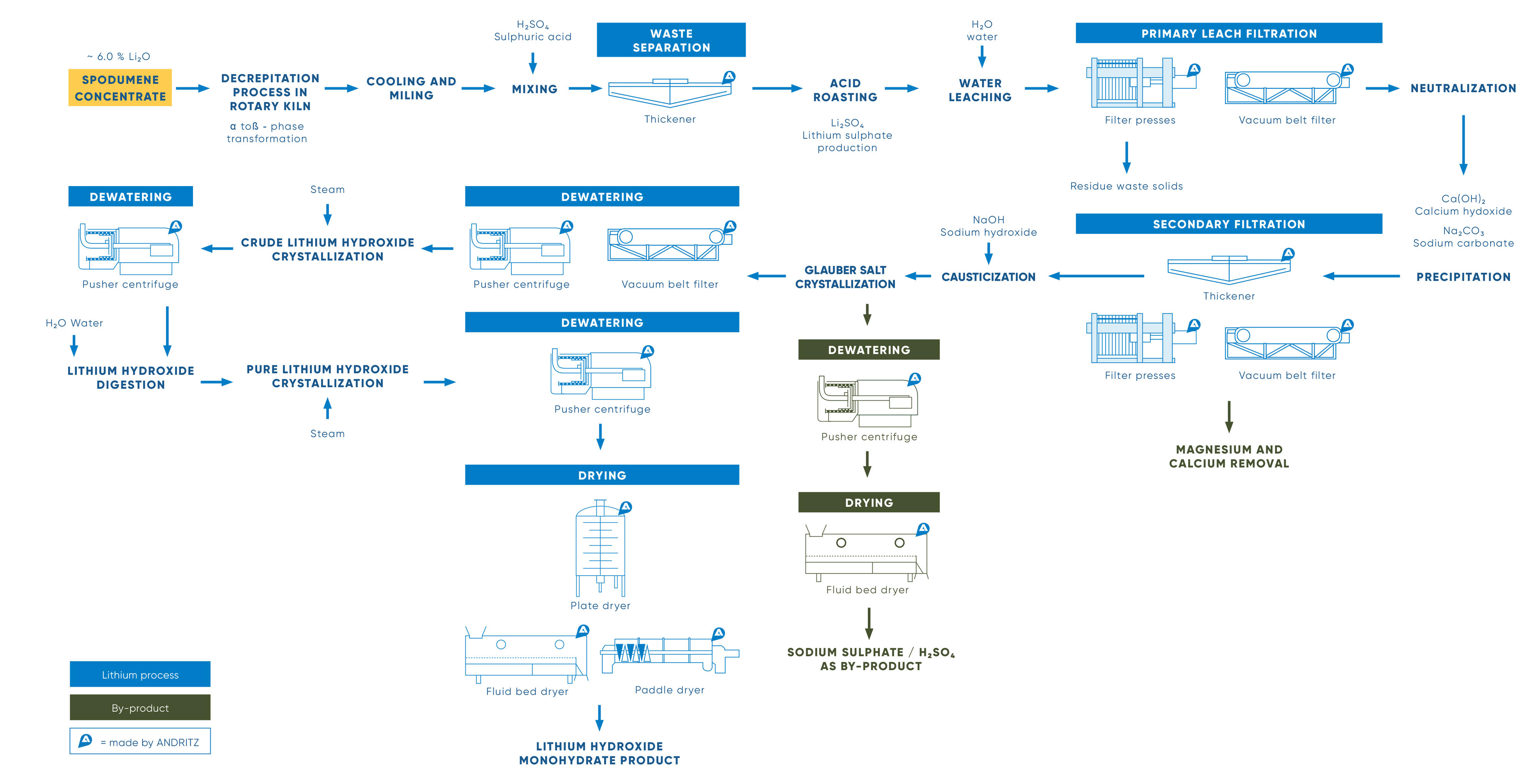

It all started in the 1960s, the first ANDRITZ pusher centrifuge for lithium carbonate, which operated for over 60 years. This represents our commitment to supplying the world’s largest lithium producers with robust separation technologies that withstand a long lifetime of continuous use.

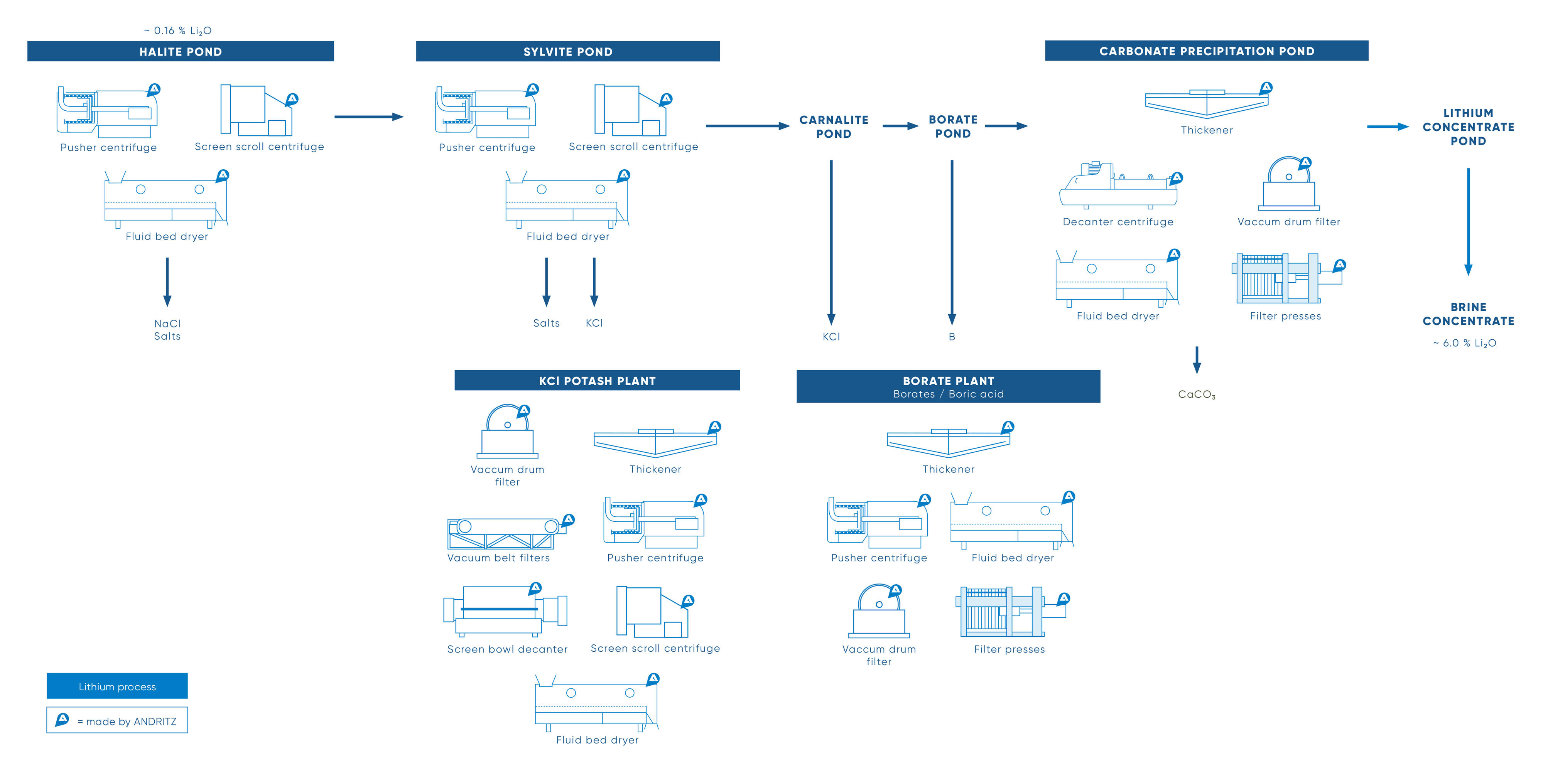

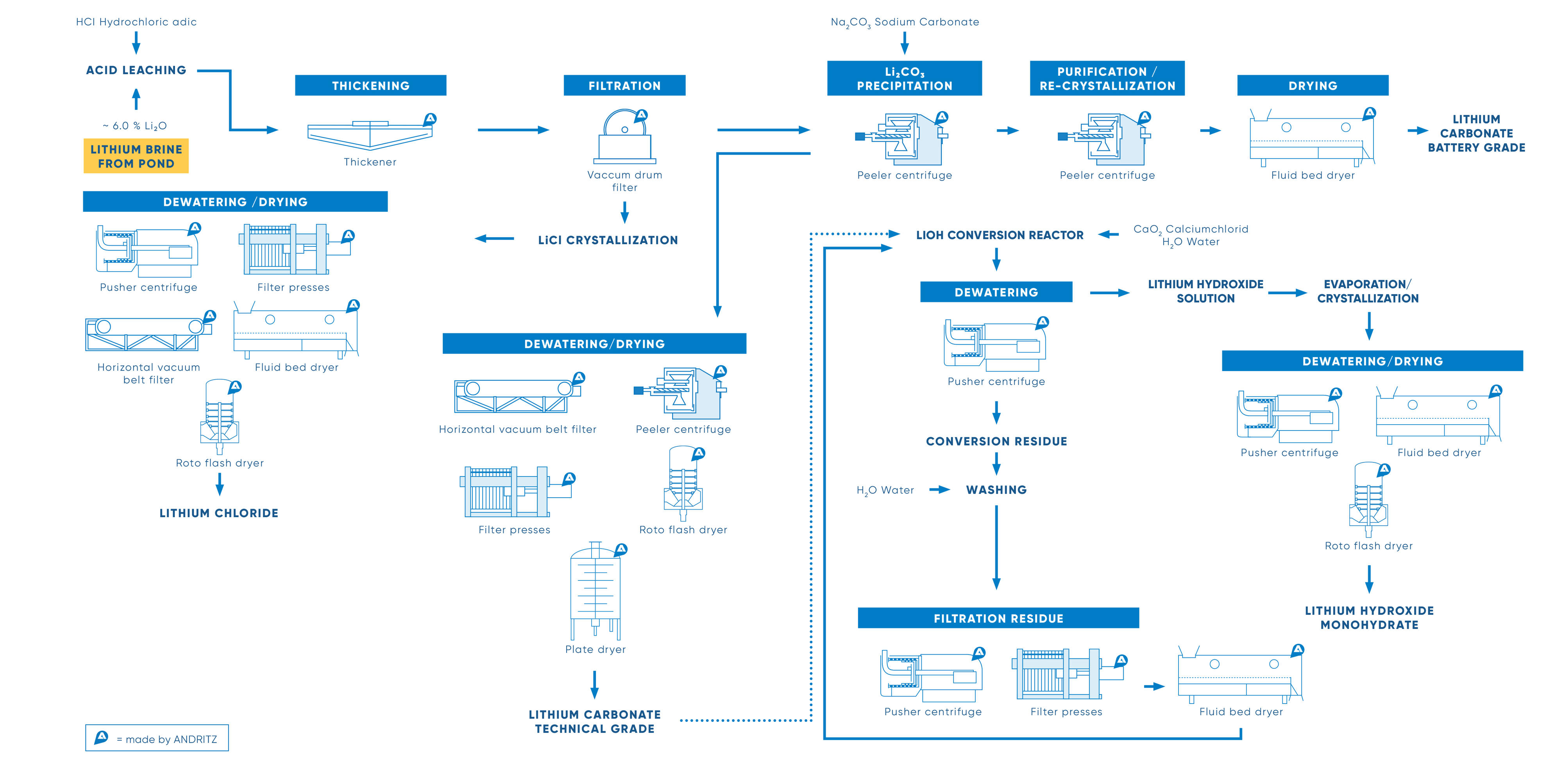

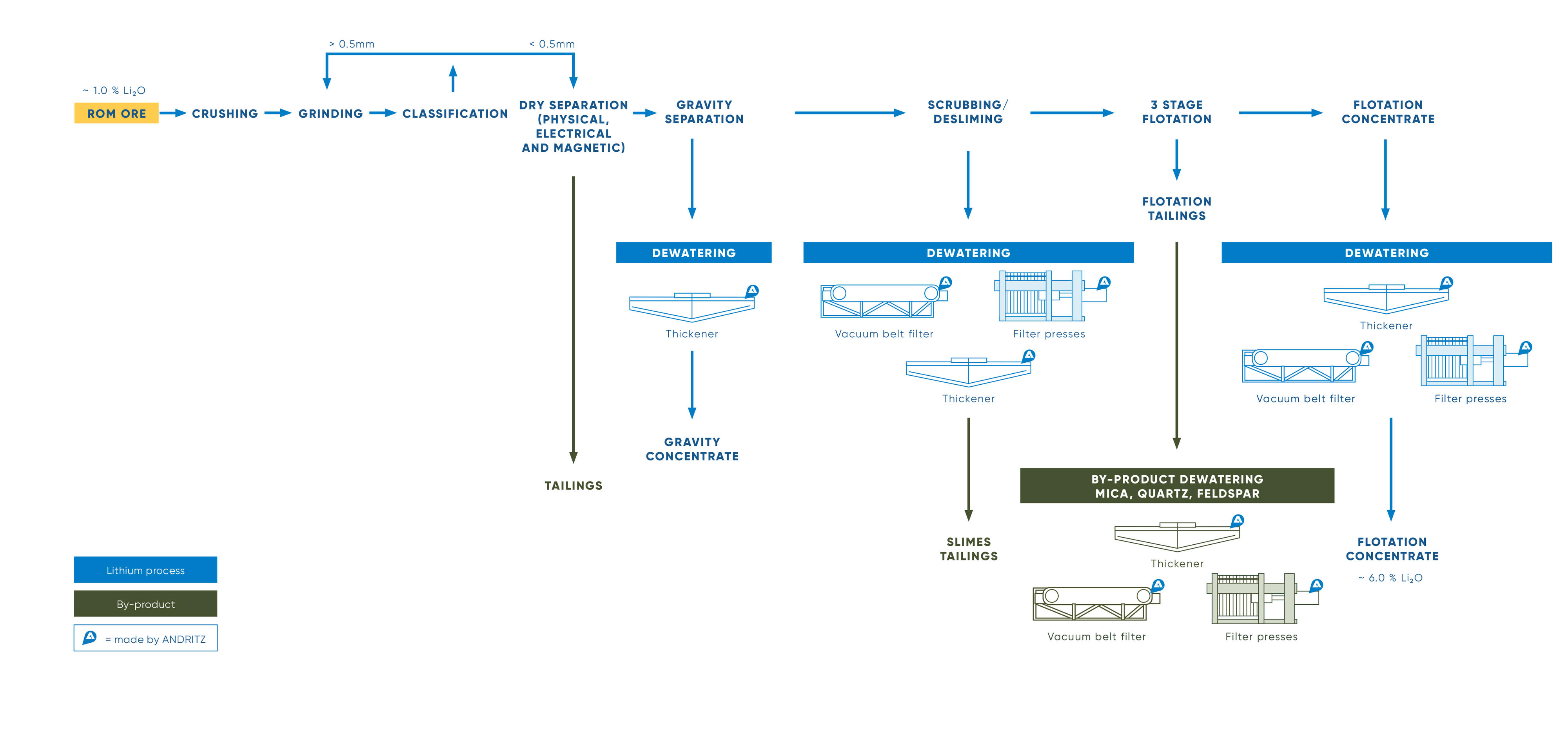

For hard rock lithium sources, we offer systems for the thickening and dewatering for both tailings and spodumene at the mine site, as well as systems for the production of lithium hydroxide and lithium carbonate and the removal of impurities at the process plant. These technologies include vacuum drum filters, vacuum belt filters, filter presses, as well as pusher and peeler centrifuges.

ANDRITZ also has the ability to provide complete dewatering and drying systems for better overall efficiency. We have global references for cases where our new technology is more efficient in the final steps than previous technologies. In addition, we are continuously developing new technologies specifically adapted for lithium mines such as Metris addIQ filter cloth tracking system.