AI-enhanced Threading Rope Monitoring

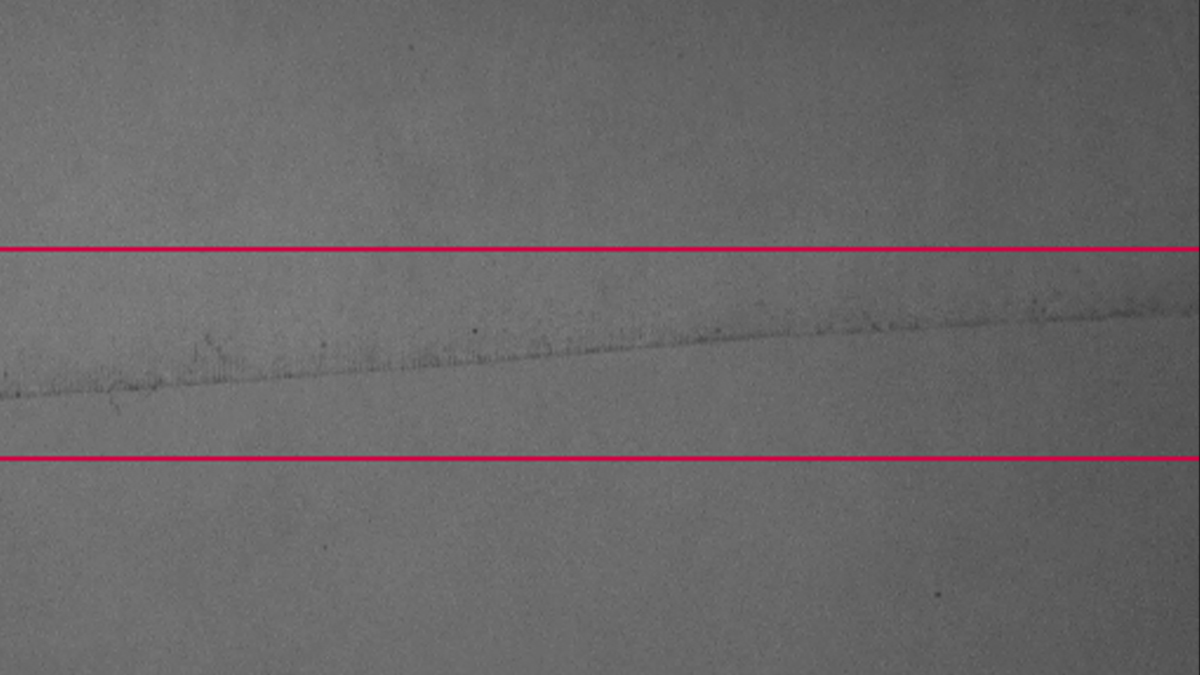

The Automatic Threading Rope Monitoring examines the condition of threading ropes and their expected lifetime 24/7 helping to prevent serious damages and expensive unplanned production shutdowns. Rope breaks can also form a safety hazard and cause severe damage to people and equipment.